RSA Cutting Technologies Ltd

We supply sawing centres for single or multiple cuts, steel or stainless steel parts or non-ferrous metals. Our sawing centres are provided with short set-up times, easy operation, high precision and high economic efficiency. They can be smoothly integrated with all subsequent steps in processes such as deburring, chamfering, measuring, washing and stacking.

Filter products and services

-

RASAPLAN XY

With RASAPLAN XY you deburr in a single work process: Work pieces are fed between two rotating brush rollers using a universal transport system. Here the tubes and profiles are turned 360° and all edges, interior and exterior, are deburred on both ends simultaneously, leaving no residue. RASAPLAN XY is a deburring module that can be integrated into any linked system.Request a Quote Supplied by RSA Cutting Technologies Ltd -

RASAPLAN XY linked system

With RASAPLAN XY you deburr in a single work process: Work pieces are fed between two rotating brush rollers using a universal transport system. Here the tubes and profiles are turned 360° and all edges, interior and exterior, are deburred on both ends simultaneously, leaving no residue. RASAPLAN XY is a deburring module that can be integrated into any linked system.Request a Quote Supplied by RSA Cutting Technologies Ltd -

Re-sharpening

As a special service, we offer you the re-sharpening of your saw blades. Afterwards, the cutting performance is partially up to 150 % higher than the output of saw blades of conventional re-sharpening services. As a result, in the life time cycle of one saw blade only costs savings of Euro 300.00 and more can be achieved, because the need for new saw blades is moreover drastically reduced due to the longer working life.Request a Quote Supplied by RSA Cutting Technologies Ltd -

ROLLER CONVEYORS

We offer a range of very solid roller conveyors in various designs with solid rollers or simple design for small loads.Request a Quote Supplied by RSA Cutting Technologies Ltd -

RSA band saw blades

The deciding factor for an optimum sawing performance is the selection of the right band saw blade. Especially for high quality bi-metal band saw blades, the right teeth profiles which may vary depending on the material cross-section are of great importance. Whether thick or thin-walled tubes and sections or solid bars with large dimensions - RSA provides you with the perfect band saw blade for your application. The know-how that we as a saw manufacturer have acquired over the years, has helped us in developing the right tools. This knowledge we would like to pass on to you. Let us assist you in selecting the right tool. Application Thin to thick wall thicknesses Tubes, sections and solid bars Common steel grades up to 1,400 N/mm² Non-ferrous metals Single and bundle cuts Sheet metal plates on panel sawsRequest a Quote Supplied by RSA Cutting Technologies Ltd -

S 225 Saw

The S 225 is a portable, compact saw for small sections, tubes and solid bars made of steel, stainless steel and non-ferrous metal designed for 90° cuts without burr.Request a Quote Supplied by RSA Cutting Technologies Ltd -

Saw blades

We manufacture our own saw blades, because only then we can be sure that our machines bring the best results for you. This is professionalism with a system: As a saw blade manufacturer, we have extensive knowledge of the optimum adaptation of tooth geometries to workpiece and material. In parallel, as a manufacturer of sawing machines, we determine the optimum forward feed and cutting speed. The result is maximum performance and quality.Request a Quote Supplied by RSA Cutting Technologies Ltd -

Saw blades

We produce our own saw blades, because this is the only way we can be sure that our machines provide the ideal results for you. This is professionalism with a system: As saw blade manufacturer we possess in-depth knowledge about the ideal adaptation of tooth geometries on work pieces and materials. As a producer of sawing machines we determine ideal feed and cutting speeds in parallel. The result is maximum performance and quality. Our brand RASABLADE stands for extremely long lifetimes and utmost cutting precision. Elaborate manufacturing procedures guarantee consistent high quality and ensure reproducible cutting results. Standard dimensions are available ex factory, special productions in juts a few days.Request a Quote Supplied by RSA Cutting Technologies Ltd -

Saw blades RASABLADE

We produce our own saw blades, because this is the only way we can be sure that our machines provide the ideal results for you. This is professionalism with a system: As saw blade manufacturer we possess in-depth knowledge about the ideal adaptation of tooth geometries on work pieces and materials. As a producer of sawing machines we determine ideal feed and cutting speeds in parallel. The result is maximum performance and quality. Our brand RASABLADE stands for extremely long lifetimes and utmost cutting precision. Elaborate manufacturing procedures guarantee consistent high quality and ensure reproducible cutting results. Standard dimensions are available ex factory, special productions in juts a few days.Request a Quote Supplied by RSA Cutting Technologies Ltd -

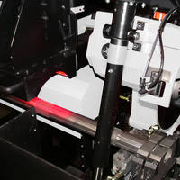

Sawing Centers

Here at RSA Cutting Systems Ltd, we manufacture and supply Sawing Centers, please contact us for more information.Request a Quote Supplied by RSA Cutting Technologies Ltd