RSA Cutting Technologies Ltd

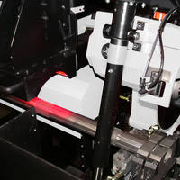

We supply sawing centres for single or multiple cuts, steel or stainless steel parts or non-ferrous metals. Our sawing centres are provided with short set-up times, easy operation, high precision and high economic efficiency. They can be smoothly integrated with all subsequent steps in processes such as deburring, chamfering, measuring, washing and stacking.

Filter products and services

-

Sawing Centres

Please contact RSA Cutting Systems Ltd for further information on our range of products and services including Sawing Centres.Request a Quote Supplied by RSA Cutting Technologies Ltd -

Sawing Machines Aluminium

Please contact RSA Cutting Systems Ltd for further information on our range of products and services including Sawing Machines Aluminium.Request a Quote Supplied by RSA Cutting Technologies Ltd -

Sawing Machines Metal

Please contact RSA Cutting Systems Ltd for further information on our range of products and services including Sawing Machines Metal.Request a Quote Supplied by RSA Cutting Technologies Ltd -

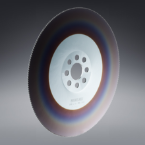

Sawing tools

Our brands RASABLADE for saw blades and RASABAND for band saw blades stand for extremely long working life and utmost cutting precision. Well-contrived manufacturing processes ensure a consistently high quality and reproducible cutting results. Standard dimensions are available from stock, purpose-built versions within a few days.Request a Quote Supplied by RSA Cutting Technologies Ltd -

Saw peripherals

We manufacture our own saw blades, because only then we can be sure that our machines bring the best results for you. This is professionalism with a system: As a saw blade manufacturer, we have extensive knowledge of the optimum adaptation of tooth geometries to workpiece and material. In parallel, as a manufacturer of sawing machines, we determine the optimum forward feed and cutting speed. The result is maximum performance and quality.Request a Quote Supplied by RSA Cutting Technologies Ltd -

Saw peripherals

As a systems supplier, we did not just design all of our saws and deburring machines modularly, so that they will fit quite smoothly into your production, but we also developed a variety of other modules with which you can optimise your production, increase quality and improve cost efficiency. Deburring, chamfering, measuring, testing, cleaning, stacking - we have the right solution for every job. Whether stand-alone or linked together as a complete line. All our modules for further processing can be freely combined and can be retrofitted at any time. They can be integrated with machines from other manufacturers- central operation from the saw's control panel is always retained.Request a Quote Supplied by RSA Cutting Technologies Ltd -

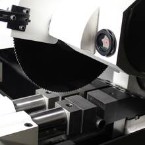

Saws

Steel saws, aluminium saws, saws for special applicationsRequest a Quote Supplied by RSA Cutting Technologies Ltd -

Saws

Whether single or multiple cuts, steel or stainless steel parts or non-ferrous metals: RSA offers you the right saw for every job. From entry models to complete modular lines. Short set-up times, easy operation, high precison and the highest economic efficiency characterise all of our products. Of course they can be smoothly integrated with all subsequent steps in machining such as deburring, cleaning and stacking. Additionally you will get the optimal tools for these jobs from us. Saw blades from our own production, so that you can fully exploit the performance of our machines.Request a Quote Supplied by RSA Cutting Technologies Ltd -

Saws for special applications

We manufacture our own saw blades, because only then we can be sure that our machines bring the best results for you. This is professionalism with a system: As a saw blade manufacturer, we have extensive knowledge of the optimum adaptation of tooth geometries to workpiece and material. In parallel, as a manufacturer of sawing machines, we determine the optimum forward feed and cutting speed. The result is maximum performance and quality.Request a Quote Supplied by RSA Cutting Technologies Ltd -

Sealing

Today, brushes not only serve to remove dirt and dust, but also for protection against it. Examples are the sealing of passages of all types against dust and noise or transport. Leading and braking of sensitive objects.Request a Quote Supplied by RSA Cutting Technologies Ltd