RSA Cutting Technologies Ltd

We supply sawing centres for single or multiple cuts, steel or stainless steel parts or non-ferrous metals. Our sawing centres are provided with short set-up times, easy operation, high precision and high economic efficiency. They can be smoothly integrated with all subsequent steps in processes such as deburring, chamfering, measuring, washing and stacking.

Filter products and services

-

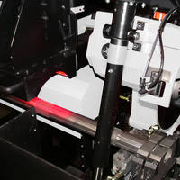

Cold Cut Metal Saw

Here at RSA Cutting Systems Ltd, we manufacture and supply Cold Cut Metal Saws, please contact us for more information.Request a Quote Supplied by RSA Cutting Technologies Ltd -

Cup and bevel brushes

Cup and bevel brushes are mainly used for removing paint, scales and corrosion. Cup brushes are intended for large areas, bevel brushes are intended for areas that are harder to reach.Request a Quote Supplied by RSA Cutting Technologies Ltd -

Customer-specific brushes

There are areas of applications where a standard brush just is not enough. This is why we supply you with exactly the special production you need. The manufacture of customer-specific versions has a long tradition here at RSA.Request a Quote Supplied by RSA Cutting Technologies Ltd -

Deburring

Increasing cost pressures and increasing demands on quality and precision processing have shaped modern manufacturing. The use of optimal deburring systems is a deciding factor in achieving the desired quality and still reducing the costs per piece. RASAPLAN deburring systems stand for maximum flexibility at minimum costs. They are based on our holistic know how as manufacturers of machines and technical high performance brushes for deburring and assure reliable and reproducible deburring at costs per piece that lie in thousandths of a cent range. Our RASAPLAN systems can be linked to any machine of other brands or can be used as a stand-alone machine.Request a Quote Supplied by RSA Cutting Technologies Ltd -

Deburring Brushes

Burrs are sharp edges that occurred during a processing or manufacturing process. RSA produces different manual and automatic deburring machines, as well as the matching brushes for deburring pipes and profiles.Request a Quote Supplied by RSA Cutting Technologies Ltd -

Deburring Machine

Here at RSA Cutting Systems Ltd, we manufacture and supply Deburring Machines, please contact us for more information.Request a Quote Supplied by RSA Cutting Technologies Ltd -

Deburring machines

The deburring of tubes and bars after the cutting is a must. But only the appropriate system allows a low cost, safe and effcient deburring. For this purpose HÄBERLE® offers various deburring machines for the deburring and chamfering of round tubes and round bars made of steel, stainless steel, non-ferrous metals, aluminium and plastics.Request a Quote Supplied by RSA Cutting Technologies Ltd -

Deburring Machines

Deburring tubes, bars, profiles and sheets after cutting is a must. But only the right system will provide low cost, reliable and immaculate deburring with the machine design and the high performance brushes being optimally adapted to the properties of the workpiece and the quality of the material. RSA as the manufacturer of the machines and high performance brushes combines is the only company to combine both scopes. You the user benefit, as this complete system allows you to always have reproducible, perfect results. Discover the advantages RSA deburring systems have to offer!Request a Quote Supplied by RSA Cutting Technologies Ltd -

Derusting

Depending on whether surfaces, edges, threads, drilled holes etc. shall be worked, there are different application for different brush types. Depending on the degree of rust, different bristles are used: Crimped steel wire is sufficient for light rust. Knotted steel wire or corded wires are used for massive rust. Crimped, plastic-coated steel wire is adequate for on-point derusting of a defined place.Request a Quote Supplied by RSA Cutting Technologies Ltd -

Descaling

Scales are a corrosion product that forms on metallic surfaces if these are subjected to high temperatures. Different brush applications are possible to remove this scale layer, depending on whether surfaces, edges or inner surfaces must be worked on and how thick the layer is.Request a Quote Supplied by RSA Cutting Technologies Ltd