RSA Cutting Technologies Ltd

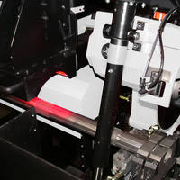

We supply sawing centres for single or multiple cuts, steel or stainless steel parts or non-ferrous metals. Our sawing centres are provided with short set-up times, easy operation, high precision and high economic efficiency. They can be smoothly integrated with all subsequent steps in processes such as deburring, chamfering, measuring, washing and stacking.

Filter products and services

-

H 6/B Saw

Cutting saw for sheet metal sectionsRequest a Quote Supplied by RSA Cutting Technologies Ltd -

H 6/B Saw

The H 25 is a small production saw for conduits and sections made of steel and stainless steel designed for diameters up to 80 mm.Request a Quote Supplied by RSA Cutting Technologies Ltd -

H 90 Saw

The H 90 is a compound mitre saw for tubes, sections and solid bars made of steel, stainless steel or non-ferrous metal.Request a Quote Supplied by RSA Cutting Technologies Ltd -

HÄBERLE® DEBURRER

The deburring of tubes and bars after the cutting is a must. But only the appropriate system allows a low cost, safe and effcient deburring. For this purpose HÄBERLE® offers various deburring machines for the deburring and chamfering of round tubes and round bars made of steel, stainless steel, non-ferrous metals, aluminium and plastics.Request a Quote Supplied by RSA Cutting Technologies Ltd -

HÄBERLE® SAW BLADES

We manufacture our own saw blades, because only then we can be sure that our machines bring the best results for you. This is professionalism with a system: As a saw blade manufacturer, we have extensive knowledge of the optimum adaptation of tooth geometries to workpiece and material. In parallel, as a manufacturer of sawing machines, we determine the optimum forward feed and cutting speed. The result is maximum performance and quality.Request a Quote Supplied by RSA Cutting Technologies Ltd -

High performance brushes

Through intensive research and development RSA further developed conventional technical brushes into intelligent industrial brushes. To this end, special types of wire were developed for various applications. This means for our customers excellent processing results in constant quality and a longer working life . The result: low costs per processed workpiece.Request a Quote Supplied by RSA Cutting Technologies Ltd -

HM-equipped saw blades

We produce our own saw blades, because this is the only way we can be sure that our machines provide the ideal results for you. This is professionalism with a system: As saw blade manufacturer we possess in-depth knowledge about the ideal adaptation of tooth geometries on work pieces and materials. As a producer of sawing machines we determine ideal feed and cutting speeds in parallel. The result is maximum performance and quality. Our brand RASABLADE stands for extremely long lifetimes and utmost cutting precision. Elaborate manufacturing procedures guarantee consistent high quality and ensure reproducible cutting results. Standard dimensions are available ex factory, special productions in juts a few days.Request a Quote Supplied by RSA Cutting Technologies Ltd -

Honing

Honing is a machining fine processing procedure for nearly all materials and is the last finishing process in production The goal is the improvement of the dimension and shape accuracy. The most well-known application cases are the piston running surfaces on cylinders of combustion engines and hydraulics construction elements.Request a Quote Supplied by RSA Cutting Technologies Ltd -

Honing brushes

Honing brushes are made with special ball bristles. We produce the bristle diameters in the tight, necessary dimensions for the different drilling diameters. Main area of application is the engine, hydraulics, pneumatics constructions and weaving technique.Request a Quote Supplied by RSA Cutting Technologies Ltd -

HR 301

The HR 301 is a single spindle deburring machine for tubes and round bars, designed for the use of a countersinking tool. Recommended starting from a diameter of min. 70 mm.Request a Quote Supplied by RSA Cutting Technologies Ltd