V and F Sheet Metal Co Ltd

V and F Sheet Metal are a UK Hampshire based sheet metal fabrication, sheet metal work and sub-contract engineering company. We provide sheet metal manufacturing services including CNC punching, CNC laser cutting, CNC bending, welding and press work. Using the latest CAD/CAM software modelling for the best accuracy and speed of sheet metal blank development for our in house CNC punching and CNC laser cutting processes. Supporting a wide range of industries in the UK from electronics to lighting, heating and audio.

Established in Fareham, Hampshire in 1985, with the ability to handle engineering projects from one off small batches of bespoke sheet metal work to high volume power press work V and F Sheet Metal are flexible enough to offer you the complete sub-contract sheet metal fabrication service for your growing company. Regular deliveries to Portsmouth, Southampton, Winchester, Eastleigh, Andover, Basingstoke and other towns in Hampshire from our factory in Fareham is easy. Over-night pallet and small package deliveries right across the UK for those who need it is offered to ease sheet metal component supply.

We have grown to a size where we can offer a complete sub-contract sheet metal fabrication and sheet metal work service to our customers right across the UK. This can include advice on the suitability of sheet metal work designs for manufacturing, sub-assembly work or sub-contract finishing and treatments to your specification e.g. zinc plating, alocrom 1200 / 1000, iridite NCP, surtec 650, silver and black anodising, powder coating, wet painting and screen printing. Continually investing in the latest CNC manufacturing equipment and CAD/CAM software enables us to offer the best combination of quality and price to suit your sub-contract engineering and sheet metal fabrication requirements.

We have a long history of working with UK based lighting companies to reduce their sheet metal fabrication costs and improve the quality of their sub-contract engineering/sheet metal work projects. With many standard CNC punching tools and material set-up costs can be kept to a minimum when considering new sheet metal fabrication projects.

- Sheet Metal Enclosures and sheet metal housings for the electronics industry

- Reflectors and sheet metal fabrications for the UK lighting industry

- Sheet Metal Perforated Ventilation and Speaker grilles for the heating and audio industries

- Front panel electronics and rack mount sheet metal work

- Welded assemblies - thin gauge to 6mm sheet metal fabrications in ferrous and non-ferrous materials

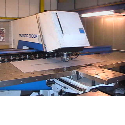

- CNC punching using Trumpf CNC punch presses

- CNC laser cutting with our Trumpf 3030 3KW fibre laser cutting machine

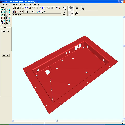

- CAD/CAM processes supported by Radan 3D and 2D software to aid CNC punching and laser cutting

- Sheet Metal CNC bending up to 3.0M long (7 press brakes), including 3 Trumpf 7036 CNC press brakes and a 3M Safan e-Brake CNC press brake

- Tig, Mig, Gas, Spot and Stud sheet metal fabrication welding capacity

- Power press sheet metal work up to 50 tons with custom press tools

Where can I get sheet metal work? Look no further if you are looking for CNC punching, CNC laser cutting, CNC bending and other sheet metal working processes:

For further information and to discuss your personal sheet metal project requirements call us on 01489 577786.

For more information about sheet metal please visit this page What is Sheet Metal Work and how is it made?

-

Sheet metal work manufactured in Great Britain

30 May 2017If you are looking for a sub-contract sheet metal working supplier in Great Britain, contact V and F Sheet Metal. With the latest laser cutting, CNC punching and CNC bending technologies supported by the latest software we can help you develop your ideas, produce samples and provide your production needs.

http://www.vandf.co.uk/blog/sheet-metal-work-manufactured-for-you-direct-in-great-britain/

-

Light fitting reflector CNC punching video

11 May 2017http://www.vandf.co.uk/blog/video-of-a-cnc-punch-press-producing-light-fitting-reflectors/

Video of one of our Trumpf CNC punch presses punching out blanks from pre-anodised reflector aluminium. Lighting reflectors can be made from a wide range of materials, try us and see what we have in stock.

-

Sheet metal work production in Great Britain 2017

4 May 2017Visit V and F Sheet Metal's blog for more stories on sheet metal work ideas and recent projects produced in 2017. From laser cutting and CNC punching through CNC bending and welding to many finishing and treatment processes. All based in Hampshire, UK.

http://www.vandf.co.uk/blog/sheet-metal-production-in-2017/

-

Sheet metal manufacturing 2017

27 April 2017If you are looking for a sheet metal worker to manufacture your components in the UK V and F Sheet Metal have a wide range of sub-contract services to offer you. From laser cutting and CNC punching using Trumpf manufacturing equipment. CNC bending with 7 CNC press brakes and a wide range of welding techniques. We can manufacture sheet metal work in all ferrous and non-ferrous materials and in a wide range of thicknesses and batch sizes to suit your purchasing requirements. http://www.vandf.co.uk/blog/sheet-metal-manufacturing-in-2017/

-

CNC punching aluminium sheet metal components

13 April 2017Interesting video demonstrating CNC punching a range of components from the same sheet of aluminium. This technique is useful when running a family of parts in production when they are all from the same sheet material and gauge.

http://www.vandf.co.uk/blog/cnc-punching-aluminium-nest-of-parts/

-

Sheet metal work projects in March 2017

10 April 2017V and F Sheet Metal have plenty of examples of recent sheet metal projects on their website. With an active blog it's well worth checking out for the latest news and ideas on efficient designing for sheet metal manufacturing http://www.vandf.co.uk/blog/sheet-metal-projects-in-march-2017-from-v-and-f-sheet-metal/

-

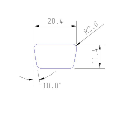

LASER CUTTING CURVED PROFILES IN ALUMINIUM SHEET METAL

6 April 2017Looking for aluminium profiles with curved shapes? With a laser cutting machine the curved profile can be easily created, such as these light fitting accessories where curves can blend perfectly back into straight lines. Not only is the profile clean but at this gauge there is no cutting burr on either side of the of the sheet metal. Each of these parts were approximately 200mm long and were cut in seconds with many being nested together from a standard 2500mm x 1250mm sheet of metal.

These are just simple parts, some laser cut components that we cut here in Fareham Hampshire can be very complex. All the parts that we laser cut are programmed with our Radan 2016 sheet metal CAD/CAM software.

Where you are looking for laser cut aluminium, stainless steel or mild steel components our Trumpf 3030 3KW laserproduce your parts. And being a fibre laser cutting machine it can cope with copper and brass sheet right up to 6mm thick. If you have a drawing you want us to look at then please send it to sales@vandf.co.uk or give our engineering team a call on 01489 577786.

-

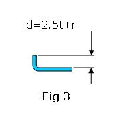

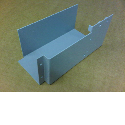

BIG EFFORT FROM A SMALL CNC PRESS BRAKE

6 April 2017Just because we use our two Trumpf 7036 CNC press brakes for bending small parts doesn’t mean they cannot help out when folding larger sections. Right up to 1M long is no problem for these great little machines and with 36 tons force they have more than enough force to fold up these zintec chassis sections. This image clearly shows the 1M tooling across the top and bottom of the press with plenty of room to access the machine for quick production bending speeds.

3D graphics and a touch sensitive screen allows the shop floor machine setters to write CNC programs really quickly, store them away on our company server and recall them for repeat batches of work whenever needed. These machines are a big part of what we do here at V and F Sheet Metal with the majority of our bending work being under 1M long but when parts are over 1M long we have our new Safan e-Brake 3M 100 ton machine to take over. This new machine can obviously bend items under 1M as well to offer a great bending service to our customers. Along with a 2.5M long CNC press brake and 2 smaller 600mm machines we have all sheet metal bending needs covered under one roof.

The sheet metal blanks in this case have been manufactured by CNC punching but they could just as easily have been laser cut and they would have bent up just the same. Having the ability to provide the machine with accurate blanks batch after batch is vital to not only ensure the accuracy of the final folded parts but in enabling quick set up of the machine tools with minimal adjustments needed before production bending can start.

Whether you have a sheet metal working project than is just a few mm across or up to 3M long we can help you here at V and F Sheet Metal, please give us a call at 0.1489 57786.

-

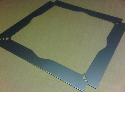

SHEET METAL FABRICATION LOCATION IDEAS

6 April 2017When we are welding just a few parts for a sheet metal project it’s easy to hold parts together either by hand or with a range of clamps. This is perfect and can produce more than acceptable results and dimensional accuracy. Similarly if the parts to be welded are quite complex or many different parts are being welded together to create a fabricated assembly we might make up a bespoke welding jig with positions of different parts fixed and allowance for shrinkage built into the weld jig. Sometimes the parts are in sufficient volumes to mean we do not want someone helping the welder but a full welding jig would be over the top, this is when the idea of building in location tags is perfect. The tags can be at the edge of a component such as the one shown above or tags into slots when more than one component are being welded together.

The advantages of using built in tags in the sheet metal parts for production are many. The accuracy can be guaranteed by the CNC punch or CNC laser program using programs like Radan sheet metal design software, the design can be such that parts cannot be assembled the wrong way round by off set tag positions and tag sizes and the tags can be puddle welded to remove any sign that they have been used by us in production so the customer only receives a part to drawing with production assembly witnesses.

Perhaps you have a sheet metal welding project that might need TiG or MiG welding in ferrous or non-ferrous metal, please call us on 01489 577786 or send us your design ideas to sales@vandf.co.uk and our engineering team will be happy to take a look and suggest methods to save time and money in production where possible.

-

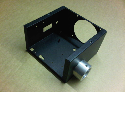

CNC PUNCHED ALUMINUM SHEET METAL

6 April 2017Here’s a perfect example of the flexibility in CNC punching that can be achieved when using a Trumpf machine. These aluminium housings and covers were CNC punched from the same sheet of material and used together to create an enclosure for a light fitting gear box. The ability to be able to mix and match components together on a single sheet of material is very useful when running production to keep batches together and ensure that the same material with bending properties is used on mating parts. Once the CNC press brakes have been set up to run a housing such as these they can go straight into the covers without a tooling change of more test samples needed for trying out the bend dimensions.

If you look carefully you can see that the housing blanks share a common slit line in both the X and Y axis. This techniques helps us save time in CNC punching and materials across the whole sheet. You can also see that we have used a corner radius tool on the covers to the left of the photo to produce a clean R5 corner in a single hit and used a knife tool to produce the holding tag for the part in the CNC nest. Both the housing and the covers where simply shaken and they then fell out of the sheet with 0.1mm corners tags, a quick de-burr and they were ready for bending.

Looking for someone to manufacture your aluminium sheet metal work by either CNC punching or laser cutting? Please give us a call on 01489 577786 or send us you drawings (DXF, DWG, STEP, SAT or PDF) to sales@vandf.co.uk and we will be happy to help you and produce some prices for different batch sizes.

-

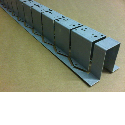

FOLDED SHEET METAL WORK WITH CNC PRESS BRAKES

6 April 2017Whenever we have a complex bracket or chassis component that needs multiple folds we tend to put it on our Trumpf 7036 CNC press brakes. If they are under 1M long these are the perfect machines to produce folded sheet metal work but if they are over 1M long such as structural sections, channels and angles then our Safan e-Brake 3M CNC press brake machine is just the thing to get the job done. With all machines using the same tooling it enables us to move parts under 1M long between all 3 machines enabling panic orders to be dealt with alongside repeat batch order bending work.

As well as all the folds you can see here that have been bent into these sheet metal components with hard V top and bottom tooling there are also a line of obround slots that have been laser cut into the component which will be used as an “easy bend” line, therefore a deliberate weak line that can be folded by hand rather than by machine tooling. In this instance we used the “easy bend” line to finish off bends on the chassis as the tooling couldn’t access the part with the other bends that were already in place. The idea of an “easy bend” can sometimes be used by the customer in their assembly of the parts if components have to be fixed in place first.

If you have a sheet metal component that needs folding then please feel free to send us your drawings to sales@vandf.co.uk or call if you need some advice on 01489 577786.

-

LASER CUTTING COPPER SHEET METAL

6 April 2017Laser cutting copper sheet metal has always been a problem for conventional CO2 laser cutting machines. With a fibre laser cutter this isn’t a problem and we have just the machine to deal with copper and brass up to 6mm thick. Our Trumpf 3030 3KW fibre laser is more than able to cut straight through thin copper sheet such as this flower. For this sheet metal project our customer needed a quick turn around. We quoted for the work, programmed it, laser cut it and sent it out in 2 days, more than meeting our customer’s expectations. The “flower” was a blank for some jewellery project and we defined the shape in Radan sheet metal software and fed a drawing back to our customer to match her simple hand sketch and verbal instructions. Now we have the design on our system server we can produce the copper “flower” again and again without any variance from batch to batch.

Perhaps you have a sheet metal manufacturing project which needs making from copper or brass sheet and haven’t been able to get it laser cut up to now, please give us a call on 01489 577786 and we will be happy to talk through your options and how we can save you money with our fibre laser cutting system.

-

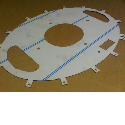

CNC PUNCHING SHEET METAL CIRCLES

6 April 2017Yes we can produce circles, semi-circles, rings and large holes in sheet metal components with our fibre laser cutter. Sometimes it suits us to us one of our Trumpf CNC punch presses to produce the sheet metal circles. Using a CNC punching technique along with radii tools called “banana” tools the circles can be produce with just a few hits. Using these special tools enables us to produce parts with very few hits, saying time and money and also reducing the cleaning up time as a secondary operation.

This view shows just how easy it is to layout a sheet of circular components using Radan sheet metal programming software. The components can be laid out to produce the maximum number of parts per sheet and even punching between the machine clamps on the sheet.

Perhaps you have a sheet metal project that needs a large circular cut-out or a disc / ring as show here. Please give us a call and we will be happy to see what we can to do to either CNC punch or laser cut the shapes you want in either ferrous or non-ferrous material in a range of thicknesses.

-

SHEET METAL BUSHES

6 April 2017Sheet metal bushes inserted in mild steel panels

Here I have found a large mild steel panel with electrical conduit knock outs pressed in by a CNC punch press and bushes being pressed in on a fly-press. We have used a fly-press in this instance to insert the bushes because the panels were quite large and the bushes were M10 which was just too big for our Haeger bush inserter to cope with.

If you are looking for any sheet metal panels with hank bushes inserted please give us a call or send over your drawings and we will be happy to advise you on bush styles and produce some prices for you.

-

PRECISION CNC LASER CUTTING COMPANY

6 April 2017Precision CNC Laser Cutting Company

V and F Sheet Metal’s precision laser cutting machine provides our customers a fast, accurate and economical option for ferrous and non-ferrous sheet metal cutting. When combined with our CNC punching facilities here in Fareham, Hampshire we offer a great all round sheet metal blank production service.

The benefits of using our Trumpf 3KW fibre laser cutter is its flexibility when it comes to material choice. From 0.3mm tin plated mild steel, to 20mm thick mild steel, 15mm stainless steel a range of aluminium alloys and being a fibre laser brass and copper up to 6mm thick are no problem. Fibre laser cutters are very accurate and incredible fast for thin gauges but even 4mm stainless steel as shown in this video is not slow. With the ability to laser cut any shape without the need for special tooling and a great edge finish the Trumpf 3030 fibre really is the machine to use for sub-contract sheet metal work. With a 3M x 1.5M bed and auto-change pallets we can process large sheets for economic material yield or small parts of sheets where needed.

From small batches of the simplest parts to large volumes of complex shapes we can handle your laser cutting requirements.

-

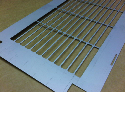

CNC PUNCHING THOUSANDS OF HOLES WITH A CLUSTER TOOL

6 April 2017These aluminium chassis components are used in electrical test equipment and are typical of the sheet metal work that we manufacture for many of our customers in the UK using CNC punching and CNC bending equipment. This batch of 25 components were then sent out to be Iridite NCP treated and then black spatter painted to our customers drawings.

When you want to produce potentially 1000′s of holes quickly and accurately in sheet metal components the best solution is to use cluster tools. These CNC punch press tools are single tools with many individual punched and dies in set patterns. On our Trumpf 3000R CNC punch press we can punch approximately 75 holes per second with our most productive tools that were used to produce this vent pattern here. We can produce complex parts with laser cut profiles and cluster punched holes patterns as a hybrid between two machines when needed bring the best strengths of each machine to a single sheet metal component.

-

FOLDING SHEET METAL BRACKETS TO YOUR DESIGN

6 April 2017Before we can fold any sheet metal work we need to produce a developed blank shape. This blank has to be the correct size so that when it’s folded up it becomes the size and shape required for the customer’s drawn design. Using our Radan CAD/CAM sheet metal software we are able to simulate the component as a 3D model and then unfold the part to create the correct blank ready for folding on one of our CNC press brakes. The blanks can be CNC punched or CNC laser cut, these brackets have been laser cut using our Trumpf 3030 3KW fibre laser, a brand new machine installed in 2013 to boost the blank production capacity along side our 2 CNC punch presses. The accuracy of the blank is essential in achieving an accurately folded sheet metal bracket and the laser certainly gives us this accuracy and control over the profile finish.

Here are the components before they have been folded up and after. The brackets are relatively simple with just 4 x 90 degree bends which have all been created with the same V block and blade tooling. The CNC program to fold up the brackets has been written at the machine and then saved away onto our company computer network for recall at a later stage if the components are manufactured again. The folding process is relatively simple using the same tooling and simply folding one bend and turning the component over and then bending again to create the Z shapes seen in the photograph.

And the final folded brackets stacked ready to be packed up and sent off to the zinc platers for treatment. These folded sheet metal brackets are typical of the smaller parts we often manufacture here at V and F Sheet Metal on our Trumpf 7036 CNC press brakes.

If you have a sheet metal design that needs folding up be it 0.7mm mild steel brackets, 2mm stainless steel angle brackets, 3mm aluminium chassis components etc. please give us a call on 01489 577786 and we will be happy to chat through your idea with you. Or perhaps you have a drawing you want to send to sales@vandf.co.uk and our engineering team will be happy to review it and produce a range of price options for you.

-

LASER CUTTING SHEET METAL WORK

6 April 2017I happened to be walking past our laser machine when the access doors were open and I took the chance to get this nice image of a full sheet of laser cut parts. The sheet of mild steel is full of the same components nested together to make the most efficient use of the material, click on the image and you will see what I mean. This “true shape” nesting is achieved automatically with our Radan CAD/CAM software which not only saves us material but can be used to trial different programs at the estimating stage before an order is placed to get the best possible price. These parts were all cut with oxygen and once they had been folded up they were zinc plated which moves all signs of any laser cutting on the surface of the sheet metal. The oxygen cut in this thin gauge produces a perfect finish without the need to do any edge de-burring operations.

If you have a ferrous or non-ferrous sheet metal project that needs laser cutting please give us a call or send us your drawings to sales@vandf.co.uk and we will be pleased to quote you.

-

SHEET METAL WORK PRODUCED IN HAMPSHIRE, UK

6 April 2017Here’s a small cross section of sheet metal work that we have produced in February 2016. Having such a wide range of customers in many different industry sectors allows us to gain a vast range of experience in manufacturing in different materials, thicknesses and sizes. From small clips and bent angles, painted front panels, anodised rear panels, zinc plated brackets, zintec folded sections, welded sheet metal fabricated assemblies we can deal with it for you here in our manufacturing site at Fareham, Hampshire.

What is sheet metal work and how is it made?, take a look at the link and we fully explain how we go about manufacturing your sheet metal work in a modern CNC controlled environment.

Looking for a new sheet metal worker based in Hampshire, UK, give V and F Sheet Metal a try and we will be happy to help you develop your ideas and produce the products you need at the right price. Call us on 01489 577786 of send your drawings to sales@vandf.co.uk

-

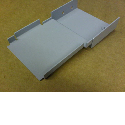

FOLDING SHEET METAL HOUSINGS

6 April 2017Our Safan e-Brake CNC press brake is more than capable of folding sheet metal work up to 3M long and with 100 tons of electric motive force you can see that these sheet metal housings were no problem. With each sheet metal housing having 8 full 90 degree bends to complete the enclosure to hold the electrical components for an emergency exit light. The order was for 500 housings and the blanks were produced on our Trumpf 200 CNC punch press to ensure they were precise and would produce an accurate component throughout the batch. The Safan e-Brake is fast, very quiet to operate and easy to program, making it the perfect machine for light sheet metal work batch production such as this.

Sheet metal housings such as these are our bread and butter and we are often found manufacturing sheet metal housings from special projects to repeating batches of 25 and 50 up to 500 like this and beyond when needed. Have a sheet metal housing and need a price, please don’t hesitate our engineering team and we will be happy to help you.

-

LASER CUTTING BRASS SHEET METAL

6 April 2017It’s not often that we get a laser cutting job that can really show off the ability of ourTrumpf 3030 fibre laser cutting machine here at V and F Sheet Metal but here is one such sheet metal project. We were asked to cut 2 decorative brass fretwork panels and our laser cutting machine was perfect for the task. The brass panels were to be manufactured from 2.5mm thick brass sheet and laser cutting was no problem for us having a fibre rather than CO2 laser cutting machine. The Trumpf fibre laser cutter is able to cut up to 6mm thick brass sheet so this order was no problem.

I took the DXF files supplied by the customer and cleaned them up. They had various errors in them including lines upon lines, corners not joining in places and more importantly points where if we had followed the drawing the brass panel would have fallen into several parts. All the drawing was cleaned up using our Radan CAD/CAM sheet metal software and small changes were made to suit laser cutting. The “clean” file was then programmed for laser cutting and the 2 panels needed laid out on a single 2500mm x 1250mm sheet.

With both parts laser cut and the sheet automatically cleared from the machine it was only left for us to remove the internal waste parts to reveal the finished brass fretwork panels.

Perhaps you have a brass sheet metal part that you didn’t realise could be laser cut with modern fibre laser technology, please give us a call on 01489 577786 or send us your drawings to sales@vandf.co.uk and we will be happy to help you and advise where you designs can be improved to save you money.

-

FOLDED SHEET METAL WORK

6 April 2017Great example of simple mild steel channel brackets that have been CNC punched and then CNC bent using one of our Trumpf 7036 CNC press brakes. These sheet metal projects are typical of the folded work that we are involved with everyday of the week for our UK customer base. Many parts that we fold up have to meet tight tolerances, such as +/- 0.2mm and we can achieve that in thin gauges due to the accuracy of the blanks we can produce via CNC punching and laser cutting as well as the high quality CNC folding facilities we have within our company.

CNC punched and CNC bent aluminium chassis trays are no problem for us. We have a range of standard CNC punch tooling that enables us to produce your electronics holes, cut-outs and profiles without the need for new tooling in the vast majority of cases. These chassis trays were produced with a protective plastic film on the outside and then treated with an Iridite NCP finish before sending to our customer. We are often asked to finish a sheet metal project be it powder coating, wet spray painting, anodising and Iriditing aluminium or zinc plating mild steel. We have a network of suppliers who can provide these finishes and offer design help for more complex parts to ensure there aren’t any problems when being treated.

These mild steel brackets were laser cut, folded on ourTrumpf 7036 CNC press brake and formed with simple tooling we made up to go on our fly-presses. They show nicely the range of manufacturing techniques that can go into the simplest of sheet metal parts.

For more information on the range of bending / folding options we can offer you from the smallest stainless steel spring clip to 3M long folded sheet metal sections. Have a sheet metal work project that needs folding, please give us a call or send your drawings to sales@vandf.co.uk and we can offer you free advice if needed and quote options to see what will work best for you.