V and F Sheet Metal Co Ltd

V and F Sheet Metal are a UK Hampshire based sheet metal fabrication, sheet metal work and sub-contract engineering company. We provide sheet metal manufacturing services including CNC punching, CNC laser cutting, CNC bending, welding and press work. Using the latest CAD/CAM software modelling for the best accuracy and speed of sheet metal blank development for our in house CNC punching and CNC laser cutting processes. Supporting a wide range of industries in the UK from electronics to lighting, heating and audio.

Established in Fareham, Hampshire in 1985, with the ability to handle engineering projects from one off small batches of bespoke sheet metal work to high volume power press work V and F Sheet Metal are flexible enough to offer you the complete sub-contract sheet metal fabrication service for your growing company. Regular deliveries to Portsmouth, Southampton, Winchester, Eastleigh, Andover, Basingstoke and other towns in Hampshire from our factory in Fareham is easy. Over-night pallet and small package deliveries right across the UK for those who need it is offered to ease sheet metal component supply.

We have grown to a size where we can offer a complete sub-contract sheet metal fabrication and sheet metal work service to our customers right across the UK. This can include advice on the suitability of sheet metal work designs for manufacturing, sub-assembly work or sub-contract finishing and treatments to your specification e.g. zinc plating, alocrom 1200 / 1000, iridite NCP, surtec 650, silver and black anodising, powder coating, wet painting and screen printing. Continually investing in the latest CNC manufacturing equipment and CAD/CAM software enables us to offer the best combination of quality and price to suit your sub-contract engineering and sheet metal fabrication requirements.

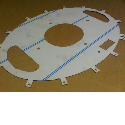

We have a long history of working with UK based lighting companies to reduce their sheet metal fabrication costs and improve the quality of their sub-contract engineering/sheet metal work projects. With many standard CNC punching tools and material set-up costs can be kept to a minimum when considering new sheet metal fabrication projects.

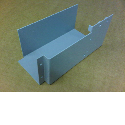

- Sheet Metal Enclosures and sheet metal housings for the electronics industry

- Reflectors and sheet metal fabrications for the UK lighting industry

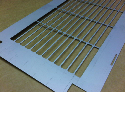

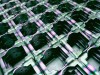

- Sheet Metal Perforated Ventilation and Speaker grilles for the heating and audio industries

- Front panel electronics and rack mount sheet metal work

- Welded assemblies - thin gauge to 6mm sheet metal fabrications in ferrous and non-ferrous materials

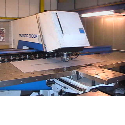

- CNC punching using Trumpf CNC punch presses

- CNC laser cutting with our Trumpf 3030 3KW fibre laser cutting machine

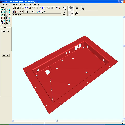

- CAD/CAM processes supported by Radan 3D and 2D software to aid CNC punching and laser cutting

- Sheet Metal CNC bending up to 3.0M long (7 press brakes), including 3 Trumpf 7036 CNC press brakes and a 3M Safan e-Brake CNC press brake

- Tig, Mig, Gas, Spot and Stud sheet metal fabrication welding capacity

- Power press sheet metal work up to 50 tons with custom press tools

Where can I get sheet metal work? Look no further if you are looking for CNC punching, CNC laser cutting, CNC bending and other sheet metal working processes:

For further information and to discuss your personal sheet metal project requirements call us on 01489 577786.

For more information about sheet metal please visit this page What is Sheet Metal Work and how is it made?

-

Looking for a sub-contract sheet metal manufacturing supplier?

16 November 2023If you're in search of a reliable sub-contract sheet metal supplier, your quest ends here. Our company prides itself on being a trusted partner for all your sheet metal needs. With a commitment to precision, quality, and timely delivery, we excel in providing customized solutions to meet your specific requirements. Our skilled team of professionals ensures that each project is executed with precision and attention to detail, guaranteeing the highest standards of craftsmanship. Whether you require components for industrial applications, construction projects, or any other sheet metal fabrication needs, we have the expertise and capabilities to deliver results that exceed expectations. Partnering with us means gaining access to a dedicated and experienced team committed to meeting your subcontracting sheet metal requirements with efficiency and excellence.

https://www.vandf.co.uk/blog/looking-for-a-sub-contract-sheet-metal-manufacturing-supplier/

-

Manufacturing sheet metal housings to your own designs

15 November 2023Manufacturing sheet metal housings is a complex and precise process that requires a harmonious blend of engineering expertise and cutting-edge technology. The journey begins with the careful selection of sheet metal, a decision influenced by factors such as the intended application, environmental conditions, and desired durability. Common choices include steel and aluminum, prized for their strength and formability. The selected metal undergoes a meticulous transformation through a series of steps, starting with cutting. Traditional methods like shearing or advanced techniques such as laser cutting define the initial shape of the housing. This phase is critical as it lays the foundation for the housing's structural integrity and functionality.

Following the cut, the sheet metal moves into the forming stage. This involves shaping the metal into the desired configuration through processes like bending, folding, or stamping. Precision is paramount during this stage to ensure uniformity and consistency in the final product. Welding may come into play, joining various components together to create a seamless, unified structure. The welding process requires a high level of skill to achieve strong and durable bonds between metal parts.

Surface finishing is the next crucial step in manufacturing sheet metal housings. Various treatments, such as powder coating or galvanization, are applied to enhance both the aesthetic appeal and the protective qualities of the housing. These treatments not only contribute to the visual aesthetics of the final product but also provide a protective layer, preventing corrosion and extending the lifespan of the housing. The choice of surface finish can be influenced by the intended environment of use, with considerations for factors like humidity, temperature, and exposure to corrosive elements.

Innovations in manufacturing techniques have played a significant role in shaping the landscape of sheet metal housing production. Advanced technologies, such as computer numerical control (CNC) machining, have elevated precision to new levels, allowing for intricate designs and complex geometries. Automation has streamlined the manufacturing process, improving efficiency and reducing the margin of error. Additionally, there is a growing emphasis on sustainability in the manufacturing industry, leading to the exploration of eco-friendly materials and processes in the production of sheet metal housings.

Sheet metal housings find application in a wide array of industries, from electronics and automotive to telecommunications and beyond. Their versatility and durability make them indispensable for protecting sensitive components and machinery, ensuring the safe and efficient operation of various devices. As technology continues to advance, the manufacturing of sheet metal housings will undoubtedly witness further innovations, pushing the boundaries of what is possible and setting new standards for quality and efficiency in the world of industrial design.

Contact V and F Sheet Metal at http://www.vandf.co.uk if you need a quote to manufacture your sheet metal housings.

-

Bespoke sheet metal boxes, housings and enclosures made in the UK

14 November 2023Bespoke sheet metal boxes, housings and enclosures made in the UK to your own designs.

Using a range of CNC press brakes to form and fold up sheet metal laser and CNC punched blanks.

https://www.vandf.co.uk/blog/custom-sheet-metal-boxes-manufactured-to-your-designs/

Ask us for a quote today on your sheet metal work.

-

Bespoke sub-contract sheet metal brackets made to your designs

13 November 2023V and F Sheet Metal have been manufacturing bespoke sheet metal brackets since the 1980s. The manufacturing is a specialized and intricate process that involves precision, attention to detail, and advanced engineering techniques. Unlike mass-produced brackets, bespoke brackets are tailor-made to meet specific design requirements, ensuring a perfect fit for the intended application. The process begins with a thorough understanding of your specifications, including size, shape, material preferences, and any specific performance criteria. Skilled engineers then use computer-aided design (CAD) software to create detailed programs, optimizing the bracket's structural integrity and functionality. The selected sheet metal, often chosen for its durability and strength, undergoes precision cutting, bending, and shaping using state-of-the-art machinery such as CNC (Computer Numerical Control) equipment. This ensures consistency and accuracy throughout the manufacturing process. The brackets may undergo additional treatments like welding, surface finishing, or coating to enhance their resistance to corrosion or wear. The final product reflects a harmonious blend of craftsmanship and technology, delivering a customized solution that precisely meets the client's needs. The manufacturing of bespoke sheet metal brackets is idea for small to larger batches sizes.

Send us your drawings and we will be happy to help you with a range of price breaks to suit your requirements.

https://www.vandf.co.uk/gallery/bracket-angle-gallery/

-

Sheet metal workers in the Southampton area of Hampshire

9 November 2023Are you looking for a sheet metal working company in the Southampton area of Hampshire? V and F Sheet Metal have been manufacturing sub-contract sheet metal components for a wide range of UK based companies for over 35 years. working with mild steel, galv and zintec, stainless steel, aluminium alloys, brass and copper sheet as well as pre-painted, spring stainless and aluminium reflector materials. Laser cutting, CNC punching and CNC bending sheet thicknesses from as low as 0.3mm up to 6mm thick. We manufacture parts for the lighting, heating, audio and electronics industries as well as a wide range of others across the UK.

https://www.vandf.co.uk/blog/southampton-sheet-metal-workers-ready-to-help-you/

If you are looking for sheet metal enclosures, front / rear panels, profiles, plates, brackets or welded assemblies ask us for a quote today.

-

Small bespoke sheet metal boxes / housings made to your own designs

8 November 2023https://www.vandf.co.uk/blog/bespoke-sheet-metal-housings-manufactured-in-the-uk/

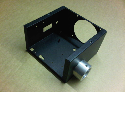

Small sheet metal boxes / housings are very versatile and commonly used containers made from thin, flat sheets of metal, such as steel, stainless steel or aluminum alloy. They are widely employed in various industries, including manufacturing, electronics, lighting, heating and construction, due to their durability and ease of fabrication. These boxes are typically formed by laser cutting or CNC punching, bending, and welding the metal sheets into a box shape. Sheet metal housings provide protection for sensitive equipment or components, serving as enclosures to shield against environmental factors like dust, moisture, accidental damage, security and electromagnetic interference. Their simple yet sturdy design makes them a practical choice for housing electronics, lighting, heating elements, fans, or other items requiring secure containment and efficient heat dissipation.

-

Stud welding bespoke sheet metal components and assemblies

7 November 2023The versatility of stud welding custom panels is very useful. It can be used with various metals and alloys, making it suitable for a wide range of design applications. Whether you’re working with stainless steel, some aluminum alloys, or mild steel, stud welding can provide a reliable fastening solution.

Furthermore, stud welding is a relatively clean process. There are no additional materials like adhesives or fasteners, reducing the risk of contamination. This is essential in industries where cleanliness and hygiene are paramount, such as the food and pharmaceutical sectors.

In summary, stud, standoff, or nut welding is a fast, strong, and versatile method for attaching fixing points to sheet metal panels. Its minimal heat-affected zone, adaptability to different materials, and cleanliness make it an ideal choice for many industries. With stud welding, you can achieve efficient and sturdy connections without compromising the integrity of your sheet metal components.

Have a sheet metal project that needs stud welding custom parts? Send us your drawings and we will be happy to help you.

https://www.vandf.co.uk/blog/stud-welding-custom-sheet-metal-work-components/

-

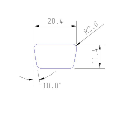

Manufacturing bespoke sheet metal brackets and angles

6 November 2023Manufacturing aluminum sheet metal brackets is a complex and precise process that involves various stages to create durable and versatile components for a wide range of applications. Aluminum, known for its lightweight and corrosion-resistant properties, is a preferred material for bracket production. The process begins with the selection of high-quality aluminum sheets, which are typically alloyed with elements like magnesium, silicon, and copper to enhance their strength and durability. These sheets are then cut into the desired dimensions using shearing, laser cutting, or punching machines. Precision is paramount in this phase to ensure that the brackets meet specific design requirements.

After cutting, the aluminum sheets are often bent or formed into the required bracket shapes. This step involves the use of specialized machinery, such as press brakes, to achieve precise angles and bends. The level of complexity in bracket design can vary significantly, from simple L-shaped brackets to more intricate configurations that demand a high degree of accuracy. The bending process is critical to ensure the brackets can securely hold and support the intended loads.

Before the brackets are formed, they may undergo additional processes to further refine their shape and properties. For example, holes and cutouts may be added through processes like punching, drilling or laser cutting to allow for fasteners, alignment, or to reduce weight. These perforations are often executed with precision to ensure that the brackets can be easily integrated into their final applications.

To enhance the aluminum brackets' durability and resistance to environmental factors, surface treatments are often applied. Anodizing is a common method used to create a protective oxide layer on the surface of the brackets, providing corrosion resistance and improved aesthetics. Other finishes, such as powder coating, painting, or even polishing, may be used to achieve specific functional or aesthetic requirements.

The use of aluminum sheet metal for bracket manufacturing offers numerous advantages. Aluminum's exceptional strength-to-weight ratio makes it ideal for applications where weight reduction is essential. Industries like aerospace, automotive, and marine benefit from the lightweight properties of aluminum brackets. Furthermore, its resistance to corrosion ensures that aluminum brackets can withstand harsh environmental conditions, making them suitable for outdoor or marine applications.

In summary, the manufacturing of aluminum sheet metal brackets is a multi-step process that requires precision, expertise, and attention to detail. From material selection to cutting, forming, finishing, and quality control, each stage contributes to the production of durable and versatile brackets. The advantages of using aluminum, including its lightweight nature and corrosion resistance, make it an ideal choice for various industries. Whether supporting heavy machinery or providing structural elements in aerospace applications, aluminum brackets play a crucial role in ensuring the structural support and alignment of various components.

https://www.vandf.co.uk/gallery/bracket-angle-gallery/

Ask us for a quote today on your next aluminium bracket project, happy to help.

-

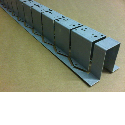

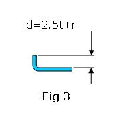

Folded sheet metal profiles

4 November 2023Folded sheet metal profiles are a versatile and integral component in various industries, from construction and automotive to aerospace and manufacturing. These profiles are created by bending and shaping flat sheets of metal, typically steel, aluminum, or stainless steel, to achieve specific geometric configurations. The folding process involves precise measurements and bending techniques, resulting in profiles with exceptional strength, durability, and dimensional accuracy. These profiles find applications in the creation of structural components, enclosures, panels, and a myriad of other products. Their ability to provide strength and rigidity while maintaining a sleek and efficient design makes folded sheet metal profiles a crucial element in modern engineering and design, contributing to the success of countless projects across different sectors.

-

Bespoke Sheet Metal Housings Manufactured in the UK

2 November 2023Bespoke sheet metal housings are metal enclosures that are custom-made to meet the specific needs of your design. They can be made from a variety of materials, including mild steel, galvanised steel, zintec, aluminium alloys and stainless steel. Bespoke sheet metal housings can be any size, shape or profile, and they can be designed to accommodate a wide range of components and assemblies.

There are many benefits to using bespoke manufactured sheet metal housings. One of the biggest benefits is that they can be tailored to meet the specific needs of the your application. This means that you can choose the exact size, shape, and material of the housing, as well as the features that are needed, such as cutouts, holes, mounting brackets, threaded inserts etc.

Another benefit of using bespoke sheet metal housings for your design is that they are very durable. Sheet metal is a very strong and rigid material, and it can withstand a lot of wear and tear. This makes bespoke sheet metal housings ideal for applications where the housing needs to be able to protect the internal components from harsh environments.

https://www.vandf.co.uk/blog/bespoke-sheet-metal-housings-manufactured-in-the-uk/

Have a design and it needs a sheet metal housing. Have a word with us or send your drawings to sales@vandf.co.uk and we will sort out quotes for you.

-

Rolling Sheet Metal Tubes

1 November 2023Rolling Sheet Metal Tubes

Sheet metal tubes are the backbone of many industries, from construction and manufacturing to automotive and aerospace. Achieving precise dimensions and consistent quality in these tubes is paramount. One technique that stands out in the world of sheet metal fabrication is the process of sheet metal rolling.

Rolling Mastery: Rolling sheet metal tubes involves passing a flat metal sheet through a series of rollers to form a cylindrical shape. This process requires a high degree of expertise and precision to ensure that the resulting tubes meet industry standards. The metal sheet may need to be run through the rollers several times to achieve the final size and shape.

Versatility: One of the primary advantages of rolling is its versatility. It can be used with various metals, including steel, aluminum, and stainless steel, allowing manufacturers to meet a wide range of application needs. Small to high volumes. No special tooling is needed to very flexible for samples and small runs.

Strength and Durability: Rolled sheet metal tubes boast enhanced strength and durability. The uniform shape and thickness contribute to their structural integrity, making them suitable for critical load-bearing applications.

Customization: Rolling allows for customization. Manufacturers can create tubes of varying diameters and lengths, ensuring they meet the exact requirements of a project. This flexibility is invaluable for industries with unique specifications.

Cost-Effective: By reducing the need for extensive welding or fabrication, rolling offers cost-effective solutions. The process minimizes material waste and labor expenses, making it an efficient choice for businesses aiming to optimize their bottom line.

https://www.vandf.co.uk/plant-list/rolling-sheet-metal/

In conclusion, the art of rolling sheet metal tubes is a testament to precision and versatility in sheet metal fabrication. It produces strong, durable, and customized tubes that meet the stringent requirements of various industries. Its cost-effectiveness and efficiency make it an indispensable technique in the world of sheet metal manufacturing.

-

Efficiency and Precision: CNC Punched Sheet Metal Rack Mount Panels

30 October 2023CNC punched sheet metal rack mount panels are the unsung heroes of modern electronics and data management. These precision-crafted panels, produced using computer numerical control (CNC) technology, play a vital role in organizing and safeguarding critical equipment.

The key advantage of CNC punching in the fabrication of rack mount panels is its unmatched precision. These panels are tailor-made to accommodate a variety of electronic components, ensuring a snug fit, optimal airflow, and efficient cable management. Whether it's for data centers, audio equipment, or industrial control systems, these panels are custom-designed to meet the exact needs of your application.

The efficiency of CNC punching is a game-changer. It allows for rapid production, ensuring that you receive your rack mount panels quickly and cost-effectively. These panels not only enhance the organization of your equipment but also provide an appealing and professional aesthetic.

In summary, CNC punched sheet metal rack mount panels represent the perfect marriage of precision and efficiency. They are the cornerstone of well-organized and functional equipment setups, ensuring that your critical electronics are both secure and easily accessible. When it comes to professional equipment management, these panels are an invaluable asset.

https://www.vandf.co.uk/blog/bespoke-cnc-punched-sheet-metal-19-rack-panels/

-

Sub-contract sheet metal work profiles produced on CNC press brakes

26 October 2023Looking for a supplier of your sheet metal components or assemblies?

Laser cutting, CNC punching and CNC bending.

Small brackets, panels, housings, chassis, long sections, enclosures, channels etc.

Aluminium, stainless steel, mild steel, pre-painted materials, copper, brass, spring stainless steel, reflector aluminium

https://www.vandf.co.uk/blog/sub-contract-sheet-metal-work-profiles-produced-on-cnc-press-brakes/

Ask us for a quote today on your next bespoke sub-contract sheet metal project.

-

Manufacturing bespoke sheet metal brackets in the UK

25 October 2023V and F Sheet Metal have been manufacturing sheet metal brackets since the 1980s. With the complete production process carried out in house from laser cutting / CNC punching to CNC folding, bush / stud insertion and welding; we offer a quick and cost effective service. Relationships with a wide range of painters. platers and anodisers enable us to offer the whole package.

https://www.vandf.co.uk/blog/manufacturing-sheet-metal-mild-steel-brackets-in-2023/

Simply send us your drawings and we will be happy to help with quotes and any design tips we can offer.

-

Manufacturing sheet metal mild steel brackets in 2023

24 October 2023Looking for a manufacturer of mild steel brackets?

Mild steel brackets are a versatile and durable type of bracket that can be used in a wide range of applications. They are relatively inexpensive to produce, and they can be easily customized to meet specific needs.

When looking for a manufacturer of mild steel brackets, there are a few things to keep in mind:

- Experience: The manufacturer should have experience in producing mild steel brackets. This will ensure that they are able to meet your specific requirements and produce high-quality brackets.

- Capabilities: The manufacturer should have the capabilities necessary to produce the type of brackets you need. This includes having the right equipment and expertise.

- Reputation: The manufacturer should have a good reputation in the industry. This can be determined by reading online reviews or asking for recommendations from other businesses.

- Price: The price of the brackets is important to consider, but it should not be the only factor. It is important to make sure that you are getting high-quality brackets at a fair price.

https://www.vandf.co.uk/blog/manufacturing-sheet-metal-mild-steel-brackets-in-2023/

Take a look at our website for more information on our services and past projects. Design tips and videos.

Send us your drawings and we will be happy to produce a quote for your next sheet metal working project.

-

CNC punching used to produce 19" rack mount ventilation panels

18 October 2023V and F Sheet Metal have been using CNC punch presses since the 1980s to produce a wide range of components for the lighting, heating, audio and electronics industries.

With a full library of standard and special CNC punch pierce and form tooling for most design needs. Producing lighting gear trays, ventilation panels, speaker brackets, 19" rack panels etc.

https://www.vandf.co.uk/tooling/what-is-cnc-punching/

Ask us for a quote today on your next project. Simple email sales@vandf.co.uk and we will do the rest.

-

Sheet metal production ideas ....

17 October 2023Take a look at our sheet metal blog for the latest news on sheet metal projects, tooling, design ideas to save time and money.

https://www.vandf.co.uk/blog/sheet-metal-production-ideas-for-companies-based-in-the-uk/

-

Sheet metal manufacturers near me Portsmouth Southampton Hampshire UK

3 October 2023How to select a sheet metal manufacturer.

http://www.vandf.co.uk/blog/sheet-metal-manufacturers-near-me-portsmouth-southampton-hampshire/

V and F Sheet Metal manufacture sheet metal work for a wide range of companies right across the UK. Ask us for a quote to day on your next sheet metal project.

-

Sheet metal subcontractor based in Hampshire UK

25 September 2023Using a sheet metal subcontractor for you sheet metal projects in 2023

http://www.vandf.co.uk/blog/sheet-metal-subcontractor-based-in-hampshire-uk/

Ask V and F Sheet Metal for a quote today.

-

SUB-CONTRACT SHEET METAL WORK: A GUIDE FOR BUYERS IN THE UK

21 September 2023Take a look at our blog post of buying sub-contract sheet metal work.

http://www.vandf.co.uk/blog/sub-contract-sheet-metal-work-a-guide-for-buyers/

-

Bespoke sheet metal laser cutting to suit your next project

20 September 2023Take a look at V and F Sheet Metal for your next sheet metal laser cutting project.

http://www.vandf.co.uk/tooling/what-is-laser-cutting/

-

Sheet metal control panels manufactured in the UK

19 September 2023Aluminium sheet metal control panels are used in a wide range of industries, including manufacturing, automotive, aerospace, pumping systems and electronics. They are durable, lightweight, and corrosion-resistant, making them ideal for applications where harsh environments or frequent cleaning is required.

http://www.vandf.co.uk/blog/manufacturing-aluminium-sheet-metal-control-panels-in-the-uk/

Ask us for a quote today on your next sheet metal project.

-

Laser cutting sheet metal panels to your own designs

23 August 2023To find out more about laser cutting sheet metal panels take a quick look at our website.

http://www.vandf.co.uk/blog/laser-cutting-sheet-metal-panels-at-v-and-f-sheet-metal/

Send us your drawings if you want a quote.

-

Bespoke sheet metal manufacturing - folding

2 August 2023Ask V and F Sheet Metal to help you out with your next sheet metal project.

http://www.vandf.co.uk/tooling/what-is-cnc-bending/

CNC laser cutting, CNC punching and CNC bending

-

The Advantages of Folding Sheet Metal Work with CNC Press Brakes

20 July 2023The Advantages of Folding Sheet Metal Work with CNC Press Brakes.

Please take a look at our website to see the advantages of folding sheet metal components, profiles and assemblies.

https://www.vandf.co.uk/blog/the-advantages-of-folding-sheet-metal-work-with-cnc-press-brakes/