Zouch Converters Ltd

At Zouch Converters, we are proud to be able to offer the most extensive range of high-performance adhesive tapes, foams and sealants across the world. Alongside our own flawless, premium products we source materials from the best manufacturers in the world. Using a consultative approach, we’ve built strong, trusted partnerships with some of the biggest brands and organisations worldwide and will continue to do so as we grow from strength to strength.

Delivering impeccable results for our clients from off-the-shelf components to bespoke design and development we cater to almost all industries from aviation and automotive to construction, healthcare and HVAC. With more than thirty years experience as industry leaders, the very latest in application technologies and unparalleled access to the most advanced materials on the market, whatever your goal is, we’re here to help you reach it.

-

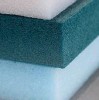

Recycled, Reconstituted and Biodegradable Foams

6 April 2023Recycled ZOUCH eFoam NXL range

A non-cross-linked closed-cell and non-toxic foam, which is flexible & a recyclable polyethylene foam. Known for its outstanding stability and recovery with unparalleled cushioning protection against impact. Anti-static and/or flame-retardant, sound-absorbing, low-abrasion, and has a minimum of 65-100% recycled resin content.

Recycled ZOUCH eFoam 3R

An environmentally friendly solution and lightweight substitute for outdoor surfaces. Made from 100% recycled post-industrial cross-linked polyethylene foam, it's ideal for energy and shock absorption, offers excellent insulation, provides drainage against wet weather conditions and is durable.

Reconstituted Foam ZOUCHrecon

Our reconstituted polyurethane foam is a practical, low-cost packaging foam used to protect products during transit and whilst being kept in storage. It's made from offcuts of polyurethane foam, which is tightly compressed and creates a recycled, multi-coloured foam material. Structurally stable, lightweight, insulating, sound-absorbent, hypoallergenic and durable, recon foam has many great benefits.

Recyclable ZOUCH eFoam R2/R/R4

This low-abrasion, fine-cell and low-density polyethylene foam is 100% recyclable, odourless and non-cross-linked. Its outstanding performance and soft-touch offer excellent cushioning protection against impact, excellent surface protection, damage reduction during transit, and a pleasing aesthetic appeal for display packaging.

ZOUCH ecoCell

Manufactured from corn starch, ZOUCH ecoCell is the most flexible and convenient packaging material for clean disposal. It can be dissolved in a sink for quick, safe and easy disposal. It even decomposes in seawater and freshwater! ZOUCH ecoCell is a biodegradable foam that is an environmentally sustainable, 100% compostable, non-toxic packaging foam.

We’re committed to increasing sustainability

That’s why we’re working alongside our manufacturing partners and customers for a better tomorrow when it comes to foam production and recycling.

As so many plastic products end up in landfill, we're producing more and more foam products that are redeveloped using recycled foam materials or biodegradable materials.

Let's start a project

We can help you achieve incredible results with your latest project no matter how complicated. We’re committed to working in close consultation to achieve incredible things.

-

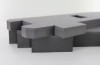

Digital Knife-Cutting to Shape and Cut Foam To Size

2 March 2023Zouch uses state-of-the-art cutting technology to manufacture and convert various foams, fabrics and sponge rubbers.

Using this digital technology, Zouch streamlines the production process and copes better with increasing numbers of short runs and customer demand. We use digital knife-cutting technology because of its ability to create bespoke shapes, no matter how complex our customer's requirements are.

Advantages of using a Digital Knife Cutter

-

High precision

-

Save on material

-

Cut to bespoke shapes

-

More flexible and efficient

-

More environmentally friendly

-

Different types of knife cutting (vibrating, round, etc.)

-

No soot and a cutting speed 3-4 times faster than a laser

Unlike traditional die-cutting, parts are cut to the highest quality and tighter tolerances, with the cutting of the edges remaining consistently high without the need to maintain and manage expensive die tools.

Before parts are produced in bulk, they are often presented to the customer as samples for approval. Digital cutting technology allows us to create perfect prototypes. After approval of samples, Zouch can start mass-producing at the push of a button, creating finished parts that mirror the original prototype.

These examples are cut from our ZOUCH eFoam XLPE 30, a fine-cell chemically cross-linked closed-cell Polyethylene block foam.

Digital knife-cutting is widely used in packaging to create bespoke shapes for any type of product needing foam protection or display. Using a CNC machine, we automatically cut various foam materials precisely to shape accurately and detail foam to specification. That means there’s no need for moulds, with a smooth cutting edge and high processing accuracy.

Frequently asked questions

What is a digital knife?A CNC (Computer Number Controlled) knife-cutting machine is a digital cutting system used for its high-precision cutting of semi-rigid and heavy materials. The cutting movement is controlled by a computer and allows for accuracy and a smooth cutting edge.

What are the advantages of a CNC cutting machine?

Using a CNC cutting machine greatly improves accuracy, reduces excess material, and improves the foam edge's quality.

Are there any disadvantages?

A CNC cutting machine is largely only used for certain thicknesses of foam, fabrics and sponger rubbers. It’s usually used for heavy or semi-rigid materials.

However, at Zouch, we’re not just a specialist manufacturer in digital cutting; we split, saw, rout, die-cut, waterjet cut, butt-weld, laminate, adhere, thermoform or compression mould, too!

That’s because we know there is no one-size-fits-all for foam production, and each project and challenge differ. We cut all our foams to size to create even the most complex shapes and sizes, whether in foam sheets, blocks or rolls.

Get in touch with a member of the Zouch team today to discuss your latest project. We’re always happy to offer non-biased advice and help you choose the right type of foam for your product.

-

-

Cost-Effective Foam Insulation For Homes

2 March 2023As energy costs rise across the UK, we have seen an increased demand for closed-cell foam. Homeowners are looking for more innovative ways to improve the energy efficiency of their homes.

A more cost-effective solution for home insulation, closed-cell polyethylene foam sheets offer real benefits to help combat price hikes and home energy efficiency. Not to mention, it also helps to reduce our carbon footprint.

Insulation creates a barrier between the inside and outside of a home, and the big benefit of better home insulation is retaining more heat. With the rising energy prices, better insulation ensures houses stay warmer for longer without paying more. The key to this is assessing advantageous areas of the home that benefit from insulation and being the most cost-effective spaces to insulate.

Walls

Heat loss | Roughly 35%

As older buildings tend to have solid walls and newer builds with cavity walls, insulation for these two types of buildings largely differ. There are now options for new builds to introduce more cost-effective insulation options.

Windows/doors

Heat loss | Roughly 25%

25% of heat is lost through home windows. Unknown to some, many double and triple-glazed windows these days have foam insulation within them. What’s more, it has the bonus of noise absorption too. Alongside internal insulation, foam tapes are used to seal crevices and seals in winter months to retain more heat.

Attic

Heat loss | Roughly 25%

Depending on the type of attic a home has, roof or floor attic insulation may be more suitable for the space. An uninsulated house can lose up to 25% of heat through the roof. Closed-cell foam is easily cut to any shape and comes in a range of thicknesses that can be glued together for added density and insulation.

Floor

Heat loss | Rough 10-15%

There’s nothing worse than getting out of bed and being greeted by a cold floor. As more and more homes opt for alternative flooring like LVT, underfloor insulation has increased in popularity too. Whilst not an essential form of home insulation, it makes a notable difference in comfort through the winter.

Radiator insulationInsulation foil reflectors are exceptionally energy efficient if you want to improve insulation from heat sources such as radiators. Easy to install, they save money by reflecting the heat into the room, so your home stays warm for longer and ensures heat isn’t wasted.

Moreover, we can create closed-cell foam sheets backed with a foil reflector to add stability, durability and extra insulation.

Seal insulation

To add to that, our self-adhesive foam sealing tape works hard to increase comfort and save money on energy costs, too. With strong adhesive backing, good cushioning, flame retardant and insulating, our sealing tapes can be used around doors and windows in the home to keep the heat from escaping.

ZOUCHseal 90

ZOUCHseal 90 is a semi-open cell PVC foam with a very low density, low force to compress and quick application without problems. ZouchSeal 90 is designed to create a watertight seal with minimal force and conforms easily to rough or irregular surfaces. It is also ideal for sealing thin gauge metals or plastics, which could deform easily under more significant pressures. To create an adequate seal, the foam must be compressed at least 30% in the thermal joint. Once in place, the foam can handle normal joint movement due to thermal expansion or environmental forces.

What are the big benefits of closed-cell polyethylene?

- Highly durable and won’t crumble

- Chemically inert and odourless, so it won’t emit gases or chemicals that could rot or tinge wood or PVC

- Non-toxic and hypoallergenic means that it’s kind to skin

- Flame-retardant and water-resistant

- Lightweight and cost-effective

- Cut to any shape and available in a range of colours

- Available in sheets, blocks and rolls

In summary, home insulation is a cost-effective way to improve your home's energy efficiency and reduce energy bills. With the rising energy cost, insulating your home is becoming an increasingly important consideration for homeowners in the UK.

At Zouch, we have an unrivalled ability to create unique, customised products that precisely meet customers' ever-evolving challenges in insulation. Our consultative approach means we’ll always find the best option for you.

Discuss your latest project with Zouch by contacting our unbiased team to discuss your challenge and options regarding insulation and closed-cell foam.

Get in touch to discuss closed-cell foam insulation.

-

Custom Cut and Designed Case Inserts for Luxury Marquetry Boards and Games

1 September 2022An award-winning designer, Alexandra Llewellyn's beautifully handcrafted and intricately detailed backgammon boards are ornaments in their own right. Her bespoke work is second to none, and she uses materials of peerless quality—sustainably sourced and unusually combined.

These entrancing games are beloved worldwide with commissions from royalty, luxury brands and well-known figures.

We recently worked with a business that has been creating luxury packaging for Alexandra Llewellyn. They needed a foam manufacturer accustomed to creating custom inserts for valuable items—after our recent work with Globe-Trotter for their Alessi Cocktail Set and Centenary Poker Box.

We were asked to create foam inserts to securely hold backgammon play pieces that would be made from a range of materials—anything from yellow agate, calf leather, marble, mother of pearl, and beyond. As some material was likely to be more delicate than others, the foam material needed to be durable, high-quality and shock absorbent. Inserts needed to be laser-cut to fit each individual backgammon play piece securely.

One of the most critical aspects of our foam was that it was chemically inert. As the play pieces are made from different materials, they needed an insert foam that wouldn't release any gases or chemicals, which tend to rot or tinge materials over time. Our foam is odourless too and doesn't retain smells, so for kits such as the Jungle Backgammon Set, which has fumed eucalyptus, the foam won't hold the scent between uses.

Considerations for luxury packaging inserts

Always consider the senses

Sight, smell and touch go a long way to creating standout packaging for beautifully crafted products. As much as the product is cherished, packaging needs to stand up to the quality of the product it protects. There can be no gassy odours. It must be durable (not crumble) and not fade (from oils on the skin or UV), and it must feel luxurious to the touch with hypoallergenic qualities for customers with sensitivities.

Quality in every aspect

Packaging can sometimes be left at the wayside when it comes to luxury items—as long as the product is outstanding, does the rest matter? Absolutely! When a consumer parts with large sums of their well-earned money, they expect their items to be well cared for and in pristine condition when not in use. Luxuriously designed packaging should consider the materials used too. Not every packaging foam is equal, and care needs to be taken when choosing a quality foam to preserve and shield an item.

Factors to consider when it comes to selecting foam range from durability, chemical inertness, flame retardancy, water resistance, weight, thickness, ability to shape and form, colour, feel (tactile), and toxicity—everything adds up to a high-quality foam that'll stand the tests of time.

The team at Zouch are well accustomed to working with brands and individuals who design and produce exquisite, high-end products. We offer unbiased advice to ensure we recommend the best products for your project.

We offer a selection of tactile foam samples ranging in colour, thickness, density and grade, so no matter your challenge, we’ve got a foam to suit your needs for luxury case inserts. Contact us for your free foam sample booklet and to discuss your latest challenge.

-

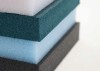

Custom Luxury Book Box Foam Case Inserts

1 September 2022Books never go out of style and from specialist agencies sending out creative PR sends for book launches, or buying a rare, first edition book that warrants and demands protection during transit—the best custom book boxes use foam protection to shield books from tearing and ruining.

Books never go out of style, and from a specialist agency sending out creative PR sends for book launches or buying a rare, first edition book that warrants and demands protection during transit—the best custom book boxes use foam protection to shield books from tearing and ruining.

Bring book boxes to life with secure foam inserts that guarantee safe and secure protection for valuable books. Customised packaging is on-trend, and whilst it looks aesthetically pleasing, consumers will be left disappointed and dissatisfied without the experience of securing items with robust protection to prevent damage.

Our best packaging solutions for books offer protective inserts made from closed-cell polyethylene foam, which can be split, sawed, routed, die-cut, water-jet cut, butt-welded, laminated, flocked, adhered, thermoform or compression moulded to create even the most complex shapes, sizes and finishes, with a range of colours available depending on your display requirements.

Our ZOUCH eFoam is a closed-cell foam that is durable, firm and lightweight, whilst working particularly hard when it comes down to shock absorption from storage and transit.

The benefits of closed-cell foam for case inserts

-

Highly durable and won’t crumble

-

Chemically inert and odourless, so it won’t emit gases or chemicals that could rot or tinge a book's cover and pages

-

Non-toxic and hypoallergenic means that it’s kind to skin

-

Flame retardant and water-resistant

-

Lightweight

-

Cut to any shape and available in a range of colours

We're a specialist manufacturer of closed-cell polyethylene foam, one of the leading choices for packaging inserts and protection. Made in Britain, we supply to five continents. Our foams can be found worldwide performing for various industries as case inserts.

Get in touch if you're interested in learning more about our highly versatile eFoam. Our expert team has decades of foam experience and can offer unbiased advice on which will work best for your challenge. We can send you a free sample booklet of our closed-cell foam and discuss specifications for your upcoming project.

-

-

Custom Flocked Foam Jewellery Box Inserts

1 September 2022We understand the importance of ensuring packaging quality is as highly finished as the product it displays. Our bespoke foam inserts are made from super soft open-cell foam, which is laminated with a pitch-black felted fabric to ensure jewellery stands out—and is not let down by unsightly or inexpensive-looking inserts.

Jewellery items are highly personal, and whilst they can be both inexpensive and costly, it doesn't make them any less meaningful to an individual. When it comes to protecting jewellery in packaging, it's essential to secure jewellery items without them slipping around quickly or becoming loose and amassing damage.

All of our foam inserts can be customised for different jewellery to securely hold rings, necklaces and earrings, as well as be cut to any shape depending on the type and size of box packaging used for display and storage.

Hypoallergenic

Our open-cell polyurethane foam is hypoallergenic and exclusively designed for contact with sensitive skin.

Odourless and chemically inert

Due to its chemical inertness, our open-cell foam doesn't release any odour and, subsequently, doesn't retain one. If perfumes, lotions or deodorisers are on the wearer's skin, they won't transfer to the foam.

Lightweight

Open-cell foam's structure ensures that it is super lightweight, and when it comes to packaging, this can be one of the key factors due to shipping and postage costs from online purchases.

High density

Despite being lightweight, open-cell foam has a very high density and is exceptionally durable, meaning it has long-lasting properties.

Moreover, the open-cell foam doesn't create or leave behind fibres, so as time goes on, the foam sees more use; it won't leave threads on jewellery—ensuring they always keep their highly polished sparkle.

Get in touch with our expert team to discuss your specific application, and we will support you from prototype to customer-ready product and are more than happy to send sample foam products at your request.

-

Foam Watch Cushion Pillows for Luxury Retail Displays

1 September 2022A luxury watch is a considerable investment; in many circumstances, they're bought in celebration or as an aesthetic to work towards. Luxury watches are timeless statement accessories and heavily impact style, personality and persona—no wonder they often come with hefty price tags, and it's not just the brand or the craftsmanship that sells a watch to an individual or collector; it's the presentation too.

The amount of time spent designing and creating luxury watches is second to none, as well as the high-quality parts used to create them. They're guaranteed to last decades, and so, when it comes to retailing items that have the potential to be displayed for extended periods, such a valuable, long to be admired timepiece must be well protected and secure until it's with its new owner.

We create durable, rounded radius foams, especially for luxury watches, using our ZOUCH eFoam IXPE 20 Polyethylene Foam.

It's a closed-cell foam with several benefits for retail displays, both in-store and windows.

Highly durable

Our eFoam durability means that each rounded radius watch pillow has stability and longevity for items that may be on display for some time. The foam will not become brittle and crumble and will last for continued reuse.

Chemically inert

As our foams are chemically inert, they will not release any gases or chemicals that tend to rot or tinge products whilst on display. Our foam is odourless, and men's and women's perfume will not pass onto the foam material between wears.

Non-toxic foam

Our eFoam is non-toxic and hypoallergenic to ensure that it is skin-friendly. Whilst many jewellery assistants wear microfibre gloves to handle luxury items; customers do not. Rest assured that our foam is kind to the skin and won't affect any customers touching watches, trying them on or coming into contact with our foam.

Flame retardant and UV resistant

The best props for window dressing are essential if you're displaying wristwatches in store windows. Our ZOUCH eFoam is flame-retardant and UV resistant, and our foam won't become discoloured when exposed to the sun for long periods.

Water-resistant

Whilst unlikely to be a problem in store, condensation build-up on windows can sometimes be an issue, and foam displays can often be left in place overnight. Our foam is waterproof due to its closed-cell nature.

Lightweight

Incredibly durable but lightweight, the ZOUCH eFoam supports watches whilst still being light for specific watch display units and cases, plinths and hanging supports for window displays.

Bespoke shapes

We can split, saw, rout, die-cut, water-jet cut, butt-weld, laminate, flock, adhere, thermoform or compression mould all of our foams to create even the most complex shapes, sizes and finishes, with a range of colours available depending on your display requirements.

At Zouch, we’re no strangers to the luxury watch industry, having created luxury foam inserts for watch straps and watch display inserts for Dean Watson. We're very proud of our work in ensuring luxury watches and jewellery are displayed to showcase their timeless appearance.

We offer a selection of tactile foam samples ranging in colour, thickness, density and grade, so no matter your challenge, we’ve got a foam to suit your display needs. Contact us for your free foam sample booklet and to discuss your latest challenge.

-

Brand New Biodegradable Packaging Foam

28 July 2022ZOUCH ecoCell is a biodegradable foam that is an environmentally sustainable, 100% compostable, non-toxic packaging foam.

- 100% compostable

- Environmentally sustainable

- Dissolves in water within 60 seconds

- Manufactured from corn starchNon-toxic and thermally insulating

- None to mild starch odour

- Quick, safe and easy disposal at home

- Biodegradable and assimilated by soil micro-organisms as food

Our eco-friendly packaging foam material can be easily cut and converted into shapes depending on requirements and is available in a range of thicknesses for impact-absorbing and thermally insulating applications. The biodegradable foam is solid white.

For the full specification of our ZOUCH ecoCell packaging foam, download our product data sheet.

-

Eco-friendly Recyclable Polyethylene Foam For Packaging And Protection

3 May 2022There are many packaging materials on the market that most would consider being recyclable but aren't or can't be recycled through your regular curbside recycling collection. As we see more and more plastic waste ends up in landfills — primarily plastic waste from packaging — it's vital that we consider the materials we're using and ensure they're more sustainable, environmentally friendly and have a much longer shelf life.

Many of our clients use protective foam packaging for case inserts, electronic protection, presentation packs and applications such as sports mats. That means that the protective foam is used repeatedly to store and preserve expensive items. At Zouch, we're making it one of our priorities to innovate and manufacture more recyclable foam for packaging.

The foam needs to be durable with outstanding performance and protect against any impact. Recyclable foam can achieve that just as well as non-recyclable foam. Eventually, when items are no longer in use or have 'seen better days, the foam protecting their article can be recycled and used for other speciality protection in the future.

We've developed two recyclable polyethylene foams specific to packaging and protection that can be cut to size and are available in a range of different densities and colours, offering various options to businesses seeking more sustainable opportunities for their projects. Don't worry about it being cut to size and there being remaining offcuts; we use all of our offcuts to create our reconstituted foam and our recycled eFoam too.Recycled ZOUCH eFoam NXL range

A non-cross-linked closed-cell and non-toxic foam, which is flexible and is recyclable polyethylene foam. It's known for its outstanding stability and recovery with unparalleled cushioning protection against impact. Anti-static and/or flame-retardant, sound-absorbing, low-abrasion, and has a minimum of 65-100% recycled resin content.

Typical applications for our recyclable foam are various packaging options from delicate items to furnishing, electronic protection and heavy-duty dunnage.

Recyclable ZOUCH eFoam R2/R3/R4

This low-abrasion, fine-cell and low-density polyethylene foam is 100% recyclable,

odourless and non-cross-linked. Its outstanding performance and soft touch offer excellent cushioning protection against impact, excellent surface protection, damage reduction during transit, and a pleasing aesthetic appeal for display packaging.

Typical applications for our recyclable eFoam are speciality packaging, case inserts, cushioned packaging, sports mats and presentation packs.There are around 80 million tonnes of polyethylene made every year throughout the world, and most of that is used for packaging. What's more, it's possible to make EPE (Expanded Polyethylene) which can be recycled and as a closed-cell, non-crosslinked foam. We're doing our best to offer this solution to our clients to drive a more sustainable route to packaging in the future.

No matter what packaging challenge you need to achieve, our expert team can work with you to design and develop products and components, choosing and using the very best recyclable foam materials for the project.

Get in touch to talk to us, and our unbiased team will be on hand to offer advice about the best recyclable foam options to get you from concept to completion. -

How to Choose a Quick Dry Open-Cell Foam for Outdoor Cushions

3 May 2022Whilst style, shape and material used for upholstery is incredibly important for aesthetics when it comes to outdoor cushions, comfort goes a long way toward use and popularity too.

Foam padding for outdoor furnishing doesn’t get any better than open-cell foam which is not only comfortable to sit on for longer periods of time but facilitates the evacuation of moisture and humidity too.

The open-cell structure of the foam ensures better airflow and good breathing capacity. That means it’s much more comfortable to sit on during the warm summer months due to its breathability and will dry quickly too. When covered in breathable fabrics the water drains through the foam to the bottom of the cushion. That makes the cushioning especially good for poolside or beach seating and general outdoor seating for the home and businesses that need a hardy foam for all weathers.

Top benefits of open-cell foam for outdoor cushions

-

Great durability with no degradation from the sun, rain and seawater

-

Its breathability ensures quick drying

-

The reticulated form promotes airflow and excellent water drainage

-

Antibacterial and non-flammable

Our open-cell foam designed for outdoor use comes in two forms, ZouchKousti Superdry Firm, ZouchKousti Superdry Medium and ZouchKousti Superdry Soft, with variations in their net density, tensile strength, compression and elongation break, which means that they’re suited to different outdoor seating applications such as boating cushions and sleeping pads, garden furniture, caravans and camping.

This type of foam is very versatile and despite being high in quality, it’s also a low-cost option.

Our foam can be cut and formed into the shape you desire and we offer environmentally friendly, hypoallergenic, quality foam products to suit all projects across cushioning.

Get in touch with our expert team to discuss your specific application and we will support you from prototype to customer-ready product.

-

-

Introducing Our All-New Compostable And Sustainable Non-Toxic Packaging Foam

3 May 2022We’re on a mission to introduce more sustainable and environmentally friendly foam options to market and we’ve just launched our new ZOUCH ecoCell.

100% compostable and environmentally sustainable, this non-toxic packaging foam is a starch-based and functional packaging material. It has exceptional cushioning and thermal insulating properties and most important, aside from protecting the product, it’s protecting our planet, too.

Our latest foam innovation, the ZOUCH ecoCell, dissolves like magic as soon as water touches it. We’re dedicated to bringing new foams into our range that are environmentally sustainable and we believe this type of foam is going to revolutionise the packaging industry.

- Rob West - Director - Zouch Converters

Manufactured from corn starch, ZOUCH ecoCell is the most flexible and convenient of any packaging material for clean disposal and goes much farther than simply recycling a foam for reuse. ZOUCH ecoCell can be dissolved in a sink for quick, safe and easy disposal. It even decomposes in seawater and freshwater and is entirely non-toxic to sea life.

The material can be easily cut and converted into shapes while being made available in a range of thicknesses for impact absorbing and thermally insulating applications. The product has been developed as an eco-conscious way to replace Low-Density Polyethylene (LDPE), Expanded Polystyrene (EPS) and Polyurethane (PU) foam products now and in the future.

Whilst many of our polyethylene foams used for packaging are recyclable, the material is processed to be reused many times, minimising the environmental impact of the material, however, our ecoCell can be disposed of by the end-user without any environmental impact.

Get in touch to discuss your latest project and requirement for packaging foam for protection with our friendly, expert team.

-

Creating Recycled Foam With Foam Offcuts

3 May 2022One of the biggest problems for foam manufacturers is the amount of waste that can potentially end up in landfills. From product packaging after gifting, to furniture cushions once they’ve seen better days, a lot of foam blocks and sheets are thrown away, which impacts the environment.

That’s why we’re taking action to move towards a more sustainable and better tomorrow by using recycled and reconstituted foam to extend the lifetime of our foam products in different industries and applications.

Generally, foam is manufactured in blocks that are then split into sheets and used for various purposes depending on the market. That means that there can be an excess of foam of varying sizes and shapes that don’t fit the requirements of other standard applications, even when bonded to form larger foam blocks or foam sheets. When that occurs, our foam offcuts create recycled foam and reconstituted foam to develop practical, recycled (and recyclable) foam applications to avoid waste from foam cut to size.

In our range of recycled foam, we have our ZOUCH eFoam 3R and a reconstituted foam ZOUCHrecon 6/8/10/12.

Recycled ZOUCH eFoam 3R

Our recycled cross-linked foam is an environmentally friendly solution and lightweight substitute for outdoor surfaces. Made from 100% recycled post-industrial cross-linked polyethylene foam, it's ideal for energy and shock absorption, offers excellent insulation, provides drainage against wet weather conditions and is durable and hard-wearing.

Typical applications for this type of recycled foam are playgrounds and play area surfaces, rooftop gardens, patios and balconies and sports and leisure facilities.

Reconstituted Foam ZOUCHrecon 6/8/10/12

Our reconstituted polyurethane foam (also known as chip foam and recon foam) is a practical, low-cost packaging foam that protects products during transit and storage. It is made from offcuts of polyurethane foam, which is tightly compressed and creates a recycled, multi-coloured foam material. Structurally stable, lightweight, insulating, sound-absorbent, hypoallergenic and durable, recon foam has a range of great benefits. Reconstituted foam is for applications that have heavy wear and high usage.

Typical applications for this type of recycled foam are protective packaging, noise control in fans & blowers, gym mats, church kneeling mats, and cushioning in furnishings such as sofas, caravans, mattresses, bar stools, chairs and more.

As so much plastic product ends up in landfills, we're producing more and more foam products that we redevelop using recycled foam materials. That means that foam is reused multiple times throughout its life cycle to benefit its protective properties fully. We’re finding that more and more of our customers are turning their ethos towards sustainability and requesting recycled foam for their products and projects.

We’ve seen reconstituted foam in retail for their upholstery and padding, often used for seating blocks for trying on footwear or for changing rooms. Due to its quirky aesthetic—more and more merchandisers are leaving the foam material bare to add an element of fun or to match terrazzo chip counter spaces, which have had a recent rise in popularity.

Recycled cross-linked foam is becoming increasingly common for outdoor spaces because it is highly resistant to wear and tear. It also has a pleasant texture and is available in different densities and colours.

No matter what you need to achieve, our expert team can work with you to design and develop products and components, choosing and using the very best recycled foam materials for the project.

Get in touch to talk to us about your latest challenge, and our unbiased team will be on hand to offer advice about the best foam options to get you from concept to completion.

-

Zouch Converters 2021 | A Year In Review

4 January 2022As ever, we’d like to thank all of our customers for their continued support throughout 2021 and for choosing Zouch as their go-to manufacturer and supplier of foam, tapes and sealing solutions.

It’s been an exciting year, and we’re very grateful for our growth, with moving to larger premises at Chase Park in Colwick, Nottingham, as well as welcoming Dave Rich and Luke Marshall-O’Brien to our team. We’ve overhauled our technology, upgraded our server and have everyone on new laptops so we can offer more efficient, faster customer service too.

The last two years have been a rollercoaster for us all, and we’ve noticed the change here at Zouch. We quickly changed our product offering back in 2020 to support the NHS and frontline staff by creating PPE Medical Grade Face Shields. We have since introduced recycled polyethylene and polyurethane foam to improve our product sustainability and work toward a better tomorrow with our customers.

It’s also been a positive and interesting year working with new businesses to develop their product with our latest foam innovations. We’ve worked with Globe-Trotter, a British manufacturer of luxury luggage, Selfridges, the high-end department stores we all know and love for its excellent window displays, and a company that needed quality foam tool trays for their end customer, Samsonite—to name but a few! We love the diverse projects and challenges we get to work on every single day.

We wish everyone a relaxed, well-deserved break over the festive season, and we’ll be closing our doors from Wednesday 22nd December and returning to work on Tuesday 4th January, ready for a new year of foam innovation.

From all of the team at Zouch,

Merry Christmas and a Happy New Year. See you in 2022!

-

Foam Display Props For Retail Windows And Merchandising

4 January 2022The gifting season is fast approaching but when it comes to gifts and promotions, there’s a consistent need for window display and in-store merchandising props to aid visual journeys when it comes to surprise and delight in a buyer’s experience.

There are important factors for visual merchandising and using foam applications for displays, promotions and POS, is a sure-fire way to get creative, be bold and keep costs down.

Colour options

Colour is especially powerful when it comes to visual merchandising and creating highly visual displays that colour coordinate with seasons or campaigns. Our foam comes in a variety of colour options to suit any artistic challenge to create impact.

Creating a focal point and telling a story

Foam can be shaped in any way imaginable to tell a story, whether it be as simple as foam lettering to highlight an area of a store or the full works when creating scenes for window displays. By having different levels of foam blocks, it creates focal points to draw the eye to products too.

Using empty space to maximise merchandising

There’s no need to waste empty space in-store and foam signage and displays are a great way to maximise the amount of merchandise on display and make the most of underutilised space.

Retail has been reshaping post-pandemic and the need for change due to online shopping has accelerated. A recent report stated that one in five UK consumers will never return to the UK high street, so it’s going to be vital to attracting attention, especially as we arrive at the busiest time of the year— from Black Friday to Christmas and the January sales.

Ideal foam applications for merchandising and eye-catching visuals:

-

Lightweight 3D POS Foam Lettering

-

Round Spherical foam (Baubles, footballs, stands)

-

Cylindrical and block foam for stands

-

Foam boards for backgrounds and window display flooring

-

Foam shapes (stars, moons, hearts, trees, snowflakes, hands)

Our ZOUCH eFoam XLPE 30A is a Closed-Cell Cross-Linked Microcellular Polyethylene Foam, which is perfect for creating solid shapes and structures for store and window displays. Popular amongst prop makers, our ZOUCH eFoam XLPE 30A boasts many benefits for display usage:

-

Available in a range of colours

-

Lightweight and cost-effective

-

Durable, strong, and tear-resistant

-

Waterproof, non-toxic, UV and flame resistant and chemically inert

-

Antibacterial for a cleaner working environment

-

Available in a range of sizes and thicknesses

-

Lamination options available for added durability

-

Flocking options available

-

Split, saw, rout, die-cut, water-jet cut, butt-weld, laminate, adhere, thermoform or compression mould options are available

We recently worked with one of the best department stores in the world to create visual props that will be used in their window displays during the seasonal period. Our Closed-Cell Polyethylene Foam has been laser cut to form hands, which will be used with a mechanism to “clap” in a red finish for a Christmas window display.

Provision of samples

We offer a closer look at our product ranges by supplying free samples, as well as project advice. Get in touch with our expert team for more information about free samples of our closed-cell polyethylene foam.

Our technical team can work with you to choose the best material for any design, so you can more effectively develop POS, props and visual displays you’re looking to create. We can split, saw, rout, die-cut, water-jet cut, butt-weld, laminate, adhere, thermoform or compression mould all of our foams to create even the most complex shapes and sizes in preparation for your project.

Simply contact us today to speak to one of our experts.

-

-

Foam Arm Positioning, Support and Pressure Cushions

4 January 2022We recently worked with a global company that focuses on the safety and comfort of patient positioning products for a variety of surgical procedures. They provide the highest quality products ensuring responsiveness and flexibility and came to Zouch looking for a foam that would be suitable for the medical environment.

Non-Toxic Open-Cell Polyurethane foam is an excellent, low-cost choice when it comes to the need for single-use cushioning for medical and surgical use, and offers an array of benefits alongside comfort for patients.

Benefits of Open-Cell Polyurethane foam

Non-toxic

Our medical-grade foams are all non-toxic, chemically inert and latex-free.

Hypoallergenic

Exclusively made for contact with the skin and designed for medical and surgical use.

Durable

High in density and exceptionally durable— even for single-use — our foams withstand wear and tear and are robust for patient protection. Our broad range of densities offers many custom options for foam shape to redistribute pressure at critical points along the arm.

Comfortable

Super soft when in contact, breathable and supportive, open-cell foam is extremely comfortable and eases pressure and is efficient at wicking moisture.

No fibres

Open-cell foam leaves no residual fibres during surgical procedures.

Our client’s brief was for arm positioning foam and when in use, it is used to relieve pressure for patients during surgery or when resting for maximum comfort. The cushions reduce and distribute pressure for the patient while in the prone or supine position.

It was essential for the foam to be comfortable and relieve pressure for the patient as well as hypoallergenic for contact with the skin. Whilst low-cost and single-use, it’s very durable which means no wear and tear, as well as no residual fibre from the foam during surgical procedures.

Other foam positioning applications

- Egg box foam that can provide extra padding and comfort.

- Chest and pelvic rolls to allow for free movement of the abdomen

- Adjustable prone leg cushion to accommodate different leg lengths

- Lateral head support to reduce pressure on the patient’s head

- Face blocks for stability and comfort in the prone position

Here at Zouch, our highly advanced technical open-cell foams are trusted by medical and health professionals across the world. They deliver smart, specialist benefits at a competitive price, while we deliver a customised, consultative service, fully focused on what you need – from the most effective materials on the market to bespoke products created just for you and your business.

Our bespoke, problem-solving approach has secured exciting projects with award-winning global brands, unlocking their potential and empowering them to grow creatively and strategically.

We offer environmentally friendly, hypoallergenic, quality foam products to suit all sectors of the health sector. Get in touch with our expert team to discuss your specific application and we will support you from prototype to customer-ready product.

-

Polyurethane and Polyethylene Foam for Halloween Props and Decorations

1 November 2021In recent years, we’ve seen an uprise in Halloween celebrations in the UK. More and more families and individuals are decorating their homes and gardens with a Spooktacular array of props. We only have to visit our local supermarkets to see shelves of ‘haunted’ decorations. It’s fair to say it’s becoming as popular as it is in the US to put effort into All Hallows Eve.

We’ve noticed an influx around this time of year for our open-cell polyurethane foam sheets due to their versatility and ease of use to shape, carve and decorate. The crafters amongst us love to create one-of-a-kind decorations that can be used year on year. Not to mention it’s a great way to get kids involved with learning about crafting and having fun whilst they create their decorations or costumes.

Our polyurethane sheets and blocks come in standard sizes, or we can cut to your desired size, as well as use adhesive to create deeper blocks if you’re looking to develop larger-scale decorations. We’d recommend our polyurethane foam for spooky tombstones, vampire coffins, “Beware” signs, and even shaping ominous-looking black cats! All you need is some craft cutting tools.

Polyurethane foam prop ideas:

- Tombstones

- Slabs for skeletons to crawl from beneath

- Scary signs

- Vampire coffins

- Black cats

Here’s a little inspiration when thinking about creating your tombstones from foam.

If you’re looking to go a little more adventurous with foam decorations and take a leaf from the professional’s book, there’s closed-cell polyethylene and EVA foam too. EVA is often used for film props and cosplay and is perfect for creating sturdy costumes and props. We often have cosplay customers looking for a rigid foam to create the faux weapons of their favourite characters and superheroes.

Closed-cell Polyethylene foam prop and costume ideas:

- Pumpkins (that you can reuse!)

- Skulls

- Bats

- Faux foam scythe

- Witches’ hats

- Superhero costumes

It’s not just about the big-scale decorations either - foam can make great, small decorations for cupcakes and cake toppers or signs to stand in your eyeball or wicked witch punch!

The benefits of using our foam:

- Smooth on both sides but can easily be manipulated for texture with tools, such as sanding for 3D realism. It also cuts and scores easily (can also be cut with a hot wire)

- Our closed-cell foam is easy to seal, prime and paint (less so with open-cell as that’s moisture absorbent)

- Dense and comes in a variety of thicknesses and can also be glued together

- Flexible, lightweight, strong and tear-resistant

- It is shaped with ease once heated.

- Waterproof (closed cell)

- Non-Toxic and Safe

- More durable than some foams

- Readily joined together with a heat gun or a glue gun

No tricks just treats

We offer a closer look at our product ranges by supplying free samples and advice. Get in touch with our expert team for more information about free samples of our foam.

Our technical team can work with you to choose the best material for any design, so you can more effectively develop the props, decorations and costumes you’re looking to create. We can split, saw, rout, die-cut, waterjet cut, butt-weld, laminate, adhere, thermoform or compression mould all of our foams to create even the most complex shapes and sizes in preparation for your project.

-

Innovative Foam Inserts for Luxury Packaging and POS

7 September 2021We're steamrolling toward the gifting period, and although it's only August, Christmas will soon be upon us with many manufacturers and companies looking to create bespoke gift and presentation boxes.

When it comes to shelf appeal, packaging can make all of the difference in catching someone's eye and choosing your products ahead of competitors. It's just as essential to achieving that high-quality finish with the outer packaging as it is to ensure the secure fit of the item within, with high-quality foam inserts.

Whether that's keeping items in place but allowing the product itself to sing or printing and laser engraving foam to delight and add a new depth of experience, foam inserts play a crucial role in the selling point of many products.

It's rare to walk down Christmas '3 for 2' aisles without seeing an abundance of gifts in beautifully designed presentation boxes. Consider high-end perfume and cosmetic gift sets with wonderfully crafted, die-cut inserts for products to fit snuggly for display when enticing customers.

Here at Zouch Converters, we create innovative foam inserts for packaging and POS, no matter the shape or amount of product that must be secured in one section. With such a variety of products that are gifted during this season, it can sometimes be challenging to find a foam insert manufacturer and supplier that can work to bespoke specifications.

Typical packaging requiring foam inserts:

- Cosmetic packaging boxes

- Watch boxes

- Jewellery presentation boxes

- Vape pen boxes

- Perfume gift boxing

- Grooming and beauty gift box packaging

- Gadget packaging boxes

- Electronic packaging boxes

- Wine glasses & decanters

We've worked with many industries and worldwide brands over the years. Our unbiased technical team will work with you to choose the correct foam for your challenge on an initial consultation. We're always happy to send out samples of our foam to ensure you're satisfied with the quality, look and feel too.

As well as foam, we're a manufacturer and supplier of adhesive tapes, so if you're looking to add even more security to your inserts (for items made of materials such a glass), we can add adhesive backing to ensure further rigidity that will mount or bond to your surface.

Benefits of our foam used for packaging inserts:

- Cost-effective, high-quality foam.

- Bespoke die-cutting or waterjet cutting to any shape, size and format.

- Laser engraving, laminating and routing are available for extra design flair

- Quickly backed with adhesive tape to keep the foam in position.

- Flame retardant, anti-bacterial, odourless and non-toxic.

- Resistant to UV, moisture and chemicals.

- Durable to stop crumbling.

- Excellent shock absorbency.

- Non Staining

- Lightweight

- Range of densities and hardness

- Available in a range of vibrant colours for display and aesthetics

- Supplied in sheets, rolls and blocks.

Don't worry if you're not entirely sure about the type of foam or cutting requirements needed; we'll work with you on your project and advise the best options for that high end, custom finish. Get in touch with us today to discuss how Zouch Converters can help.

-

Zouch Converters Move Premises

7 September 2021We are very excited to announce that our growing team has moved into a new state of the art office space. We’ve been at Regent Street in Nottingham for 3 years and as we continue to grow and expand our offering, we found we were in need of larger premises to allow our team to continue providing the quality service we offer to all our customers across the UK and internationally.

After numerous office viewings in and around Nottingham, we’re pleased to report that our new address is:

Zouch Converters Ltd,

Unit 4 Chase Park,

Colwick, Nottingham,

NG2 4GT,

United Kingdom.

Most importantly, our move won’t affect any upcoming projects for our customers. Our office hours will remain the same and manufacturing will remain at a central location in the Midlands. It’s business as usual! If you have any questions or concerns about our office move, please feel free to contact us.

The move is a new chapter in Zouch’s history and we look forward to sharing our space and welcoming current and future customers alike. Thank you for everyone’s continued support over the last year and throughout our move. It’s always appreciated.

Our team continues to expand with recent acquisitions in our Sales Manager Dave Rich, and also Luke Marshall-O'Brien joining us as Sales Support Coordinator.

We pride ourselves on ensuring that we offer unbiased advice with over five decades of industry-leading experience as a foam manufacturer. We’re at the forefront of the latest in foam application technologies and have unparalleled access to the most advanced materials on the market. Supplying exceptional foam products across five continents, we’re here to support you with your latest project from conception to completion.

Like to find out more about what we do? Just get in touch. We’re always happy to discuss projects and develop innovative ways of working together.

-

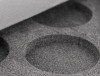

Bespoke Laser Engraved Polyethylene Foam Tool Tray Inserts

7 September 2021We recently worked with a company that needed project support with a tool tray for their end customer, Samsonite. As a big international brand in luggage manufacturer and retail — known for their quality and robust products — the tool tray inserts needed to equal that characteristic quality consumers expect from Samsonite products.

Samsonite luggage is known to last for decades due to the amount of research and development they put into all of the material used in their products. That’s why we recommended our ZOUCH eFoam IXPE 30SD product to our customer, which is a physically cross-linked closed-cell static dissipative Polyethylene foam.

Our unique formulation of this grade typically overcomes the problems associated with a Polyethylene foam suitable for use in packaging and handling ESD (Electrostatic Discharge) sensitive equipment. The Static Dissipative range of eFoam combines all the general properties of a typical Polyethylene foam but has modifications in place including surface treatment with chemicals, chemical additives such as amides and amines, as well as conductive fillers which give an overall longer lasting resistivity and performance.

It’s mainly used for the electronic industry as it’s a static-safe foam, minimising friction and material charging to keep secure components safe from the build-up and discharge of static energy.

Shock absorbent

The independent, closed-cell structure of our IXPE foam makes it especially compact and robust, which means that it doesn’t crumble or go brittle over time. It can withstand handling well and is shock absorbent, making it a choice material for transit.

Waterproof

The polyethylene closed-cell foam structure makes our ZOUCH eFoam waterproof and keeps internal products safe from any dampness and condensation encountered whilst in storage or during transit.

Mould and stain resistant

Our IXPE foam has been irradiated by a high energy electron beam, meaning the foam is protected and defends against the growth of mould and bacteria, as well as not transferring colour to the packaged product, and is easy to clean and sanitise.

High strength to weight ratio

Our eFoam is lightweight but incredibly strong to combat any wear and tear. It’s especially good for transit, keeping delivery and shipping costs low due to its weight compared to other foam.

Cushioning

The robust, solid nature of closed-foam offers excellent cushioning protection for products and combined with custom cutouts for each item, it lends itself to very secure packaging.

Other key benefits of polyethylene foam:

- Thermally insulated

- Hypoallergenic

- Cost-effective

- Odourless

- Low shred

When it came to the Samsonite tool trays, they needed to be customised for specific tools and component trays and with our ability to rout, waterjet cut, print and laser engrave, we were able to combine an excellent way of protecting the equipment and offer a slick bespoke presentation of the product too.

At Zouch, when it comes to packaging, protecting and presenting your products, we take a creative approach. Our in-depth understanding of the properties and potential of polyethylene foam means we can develop almost any design, no matter how complex into a lightweight, durable, bespoke piece that really performs for your brand and product.

Whatever you’d like to achieve, our expert team can work with you to design and develop products and components, choosing and using the very best materials for the job. We can split, saw, rout, die-cut, water-jet cut, butt-weld, laminate, adhere, thermoform or compression mould all of our foams to create even the most complex shapes and sizes, so get in touch about your latest challenge.

-

Custom Polyethylene Foam Tool Shadow Boards

7 September 2021Shadow boards are a device designed to organise a set of tools. The board outlines custom-cuts (silhouettes) where individual tools should be placed when they are not in use.

This very easily and quickly enables employees and workers to ascertain when (and which) device is missing from a kit and make for an efficient, uncluttered, and straightforward storage option for workspaces and work vehicles.

Benefits of Tool Shadow Boards:

- Improves accountability

- Health and safety compliance

- Uncluttered workspaces

- Efficient and simple

- Minimise inventory

- Easy to keep clean and sanitise

The great advantage of shadow boards is that they're designed bespoke to a customers' requirements, from size and density to colour and each tool's size, shape, and depth. However, they're not just for the use of tools and can accommodate many different industries, from quality inspection processes, cleaning carts, postal rooms, photography equipment and medical instruments.

Closed Cell Polyethylene Foam for Tool Shadow Boards

Our PE foam is low-cost, lightweight, and created from high-performance materials we're proud to produce. Robust and made using physical manufactured (IXPE) and chemical cross-linking (XLPE), our tool shadow boards are durable and rugged for the working environment.

The range includes ethylene copolymer, conductive and static-dissipative foams, and flame retardant and antibacterial grades in various densities, colours and sizes. Each one is non-toxic, thermally insulating and resistant to UV, moisture and chemicals. We also produce bespoke grades for demanding conditions, such as different temperatures and shock absorption during transportation getting from one job to another.

Closed-cell polyethylene offers real advantages over traditional rubber or sponge materials with a high strength-to-weight ratio, attractive aesthetics and low odour.

Why choose closed-cell foam for your tool shadow board?

- Available in a range of colours for easy identification

- Lightweight and cost-effective

- Durable, strong, and tear-resistant

- Waterproof, non-toxic, UV and chemically resistant

- Antibacterial for a cleaner working environment

- Available in a range of sizes and thicknesses

- Lamination options available added durability

One of our most rigid and most repeatedly used foams for protection in packaging and storage.

We can split, saw, rout, die-cut, waterjet cut, butt-weld, laminate, adhere, thermoform or compression mould and cut to size all of our foams, to create even the most complex shapes and sizes. We also supply our polyethylene foam in sheets, rolls and blocks.

Are you interested in receiving sample foam brochures from the team at Zouch Converters? Simply get in touch via our online form, email at sales@zouchconverters.co.uk or call us on +44 (0) 115 856 2025.

-

Custom Foam Inserts for Damage Protection

7 September 2021Our custom foam inserts offer quality protection for packaging, whether that's for single trip transit protection or to keep fragile items in place for gift sets and commercial packaging. Foam inserts reduce shock and vibration, preventing items from suffering breakages from any accidental damage.

Damage to items during transit or finding an item broken after purchase can negatively affect a business. Not only to the level of returns or replacements that have to be shipped at a cost to the industry but also to the company's credibility, with potential surges in bad reviews from customers.

The quality of the fit for closed-cell foam for packaging and the consideration of the shape required for the insert is vital. Poorly shaped or ill-considered placements can hinder compatibility and still lead to damage due to loose fittings or ones that are too tight.

When it comes to Zouch eFoam, we've expertly developed a range of closed-cell polyethylene (PE) foams for packaging. Our packaging foams offer absolute protection during transit to precious and fragile items such as glassware, jewellery, watches, occasion gifting and more.

Our foam is made using physical manufacture (IXPE) and chemical cross-linking (XLPE), which means it's exceptionally robust and durable and is available in extruded sheets, rolls and blocks.

Key benefits of our closed-cell foam for packaging:

- Cost-effective when it comes to high and low volumes.

- Despite the low costs, the quality of the foam is high.

- Reduces any damage to minimise costs for returns/replacements.

- Can be custom die-cut or water-jet cut to any shape.

- Laser engraving and routing are also available.

- Easily backed with adhesive tape to keep the foam in position.

- Flame retardant, anti-bacterial and non-toxic.

- Resistant to UV, moisture and chemicals.

- Durable to stop crumbling.

We understand the importance of ensuring items that are being shipped or stored with packaging for protection and presentation purposes are secure and presented with care. Our expert team takes an unbiased approach to recommend foam and always suggests the most suitable type for your requirements. We can work with you from start to finish and custom-circle and shape foam to suit even the most demanding items.

We can split, saw, rout, die-cut, water-jet cut, butt-weld, laminate, adhere, thermoform or compression mould and cut to size all of our foams, to create even the most complex shapes and sizes. We can supply our polyethylene foam in sheets, rolls and blocks.

Get in touch to discuss your latest challenge with our team to achieve the very best result for your packaging requirements.

-

Introducing our range of Recycled Foam

26 August 2021Committed to increasing sustainability, we're working alongside our manufacturing partners and customers for a better tomorrow when it comes to foam production and recycling.

As so much plastic product ends up in landfills, we're producing more and more foam products that are redeveloped using recycled foam materials. That means that foam is reused multiple times throughout its life cycle to benefit its protective properties fully.

Our range includes:

- Non-cross-linked closed-cell and non-toxic foam

- Recycled cross-linked foam

- Reconstituted polyurethane foam

- Low-abrasion, fine-cell and low-density polyethylene foam

Find out more about our recycled foam products to use in your latest projects and applications across a range of industries...

-

Open Cell Polyurethane Foam For Anti Reflux Baby Pram Wedge Pillows

26 July 2021Our highly advanced technical open-cell foams are trusted by health professionals worldwide. Skin-friendly, hypoallergenic and super soft, they're perfect for medical use, cosmetics and the baby market.

Our high-density polyurethane foam has outstanding firmness, making it comfortable and supportive when seated or lying down for long periods. That makes our open-cell foam ideal for use in baby pram pillows and cushions. -

Foam Polyurethane Sheets and Blocks for Enhanced Foam Applications

26 July 2021Our in-house design and development engineers are constantly focused on optimum comfort and cost-effectiveness as well as on reducing environmental impact.

Due to its flexibility, it’s possible to form polyurethane into almost any variety of shapes and is available in blocks, peeled rolls or sheets as standard. -

We supply exceptional foam products across five continents

26 July 2021At Zouch Converters, we're manufacturers, converters and suppliers of the world’s most extensive range of high-performance adhesive tapes, foams and sealants.

With over three decades of industry-leading experience as foam manufacturer, we’re at the forefront of the latest in foam application technologies and are unparalleled access to the most advanced materials on the market.